davedj1

Veteran Member

Looks real nice Mick. Keep up the good work. I know nearing the end of my build I wouldn't put oil in the motor until the time came to fire it up, I was afraid I would rush things if the motor was ready to go.

I've managed to get quite a bit done lately, just not had a chance to update this thread.

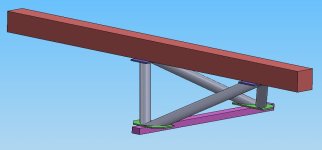

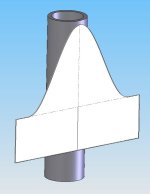

The wedge is now fully welded together and to the slider. The beams are now welded along their entire length too.

View attachment 309256 View attachment 309264

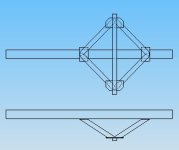

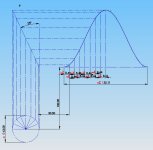

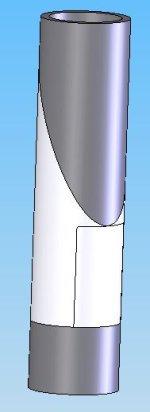

I made some precision chamfers on the slider clamps using the angle grinderThe angle is a pretty good match to the inside of the beam.

View attachment 309258

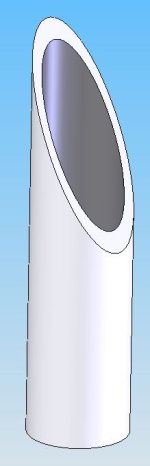

The foot now has a nice thick lump of plate welded on to reinforce it. I still need to add some pointy bits to stop the log sliding off the foot.

View attachment 309263

The best news of all is that I have had the wedge running back and forth under air pressure. I shall put a short video on YouTube soon.

At 90 PSI I even managed to split some pine pallet slats. The movement is very jerky under air pressure, but no load cylinder extension takes about 2 seconds. If it's that quick under hydraulic power I'll be impressed, but I'm not holding out too much hope yet.

I've managed to get quite a bit done lately, just not had a chance to update this thread.

The wedge is now fully welded together and to the slider. The beams are now welded along their entire length too.

View attachment 309256 View attachment 309264

I made some precision chamfers on the slider clamps using the angle grinderThe angle is a pretty good match to the inside of the beam.

View attachment 309258

The foot now has a nice thick lump of plate welded on to reinforce it. I still need to add some pointy bits to stop the log sliding off the foot.

View attachment 309263

The best news of all is that I have had the wedge running back and forth under air pressure. I shall put a short video on YouTube soon.

At 90 PSI I even managed to split some pine pallet slats. The movement is very jerky under air pressure, but no load cylinder extension takes about 2 seconds. If it's that quick under hydraulic power I'll be impressed, but I'm not holding out too much hope yet.

Very nice Mick! Nothing quite like the having one of our creations come to life is there? LOL

What's the scoop on the D90 series truck?

dave

Looks good Mick, the wedge slide should hold up well. A few bits to consider, on your base to keep log on the foot a piece of pipe 3 or 4" dia. about 1/2" tall split into two halves welded on with a short gap between them, so it is oblong rather than round. Then at the web part of the foot weld a plate from the beam to the foot, should keep you from having any problems in the future. If possible running your hydraulic lines to a valve close to the cylinder, for safety, a lot of wood may need to be held in place until the wedge has it and it will be hard to do from your tractor.

Nice job, I like the access to all the machining equipment.

Randy

You want the valve so it is an easy reach between the hand steadying a block on the beam and the hand running the valve. Usually right beside and a bit above the wedge in it's closed position with the handle in neutral straight up. Any thought to a wood striping device near the head of the cylinder that will pop off a stuck block on the return stroke without you twisting or cutting them off?

.... It didnt take us much concideration before adding that feature to our logsplitter, after it happened the first time

Yes indeed and the same species will vary with where the tree grew. A yellow birch that grew on an edge of a field will have solid knots in every block and the outside grain will look like it was braided by a demented demon. Unless your wedge is the full width of the block it will pass all the way to the foot without a crack coming through to the top of the block and then the block wrapped around your wedge just wags back and forth like a rooster on a hen. The same species growing just a hundred yards inside the tree line will have a nice straight and clear grain that will slab off easily with a four pound axe.Yes, agreed on the valve position.

The stripping device is something I remember seeing on some designs, it seems to have unintentionally fallen off my mental design pad. I may wait and see whether I actually need such a feature. I guess tendancy to stick/ease of splitting varies with types of wood.