OP

boggen

Elite Member

- Joined

- Feb 22, 2011

- Messages

- 3,829

- Location

- Trivoli, IL

- Tractor

- SSTT (Sideways Snake Tain Tractor) and STB (sideways train box) tractor, dirt harvester

i think i have something for a hyd motor. that is better setup for "in wheel" motor. vs a typical hyd motor.

been trying for a variable displacement hyd motor for the transport wheels, but i just do not see it happening.

bent axial hyd motor. i think i can do, but with a twist. it took a quick spread sheet for miles per hour to inches per minute, wheel circumference, and revolutions per minute. to make the push.

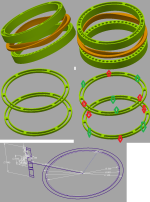

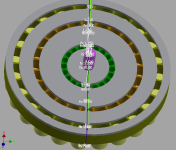

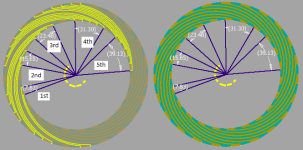

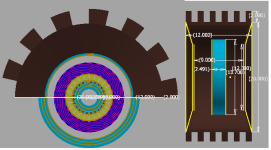

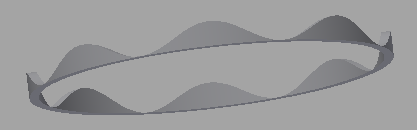

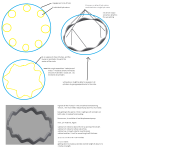

below = a swash plate?!? or rather bent axial pump, and instead of cylinders inside of the bent axial pump running at 45 degrees. thought about letting the cylinders run across humps on a ring.

more humps = slower RPM's.

less humps = higher RPMs,

more humps = a "higher" min RPM

less humps = a "smaller" min RPM

min RPM = amount of RPM that would be needed to keep the wheel spinning. without causing locking up problems. this is a bigger one for me, and possibly getting near "creeper gear" like doings.

more humps = more torque

less humps = less torque

more humps = act like another hyd motor being added in parrallel

1 hump = act like a single hyd motor.

height of the a "wave" errr humps = length of cylinders

distance from peak to peak and GPM (gallons per minute) of hyd oil, and diameter of cylinders and length of cylinders, and amount of them between peak to peak all multiplied by humps on ring = RPM (revolutions per minute)

1 hump = a flat ring, and might as resemble a bent axial pump

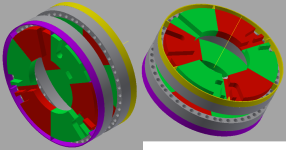

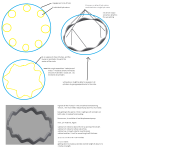

2 humps = getting symetrical and applying even pressure to each half

3 humps = i would think, would be min, to basically hold things together. might resemble a planetary gear, with 3 plant gears.

4 plus humps = just adding more torque and reducing RPM's if staying with exact same GPM of hyd oil.

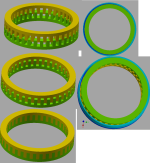

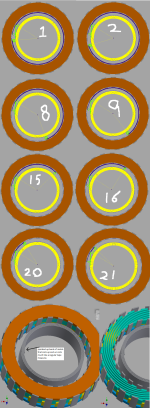

thinking i might be able to use some "plates" with holes/slots put into them to act like valves possibly. so i can switch things around to allow series vs parallel combinations, and in essence gearing. for GPM of hyd oil.

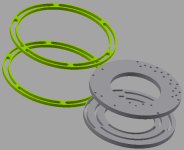

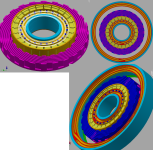

i think i might be able to get away from all gears (spur to planetary) gears completely for transmission like doings, and turn this hyd motor, directly into a rim, or setup that might mimic a electrical wheel motor.

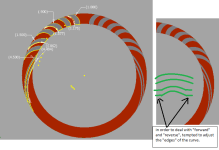

if i keep the humps completely symmetrical, i should be able to "reverse" flow of hyd oil. and get forward and reverse out of this hyd motor. that would mean hyd cylinders would need to be perpendicular to the this waved ring.

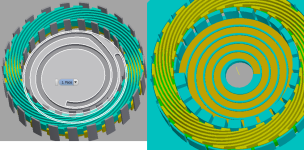

==============

hhhmmmssss never really thought about it, changing angle of hyd cylinder to the waved ring. about all that would do is change length of the cylinders, in a fix displacement pump. and change the load points. na.. as cylinders contract, it would be counter productive.

perhaps instead of angling cylinders in line with the ring, perhaps angling the hyd cylinders in towards the center of the ring. na... that would change direction of were power is being transfered to. i would need to "mirror" every cylinder on opposite side of the ring.

================

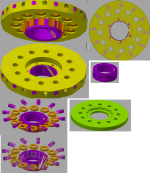

on other hand, maybe i can make this a variable displacement pump. by some how moving this waved ring further away from the cylinder block. in which case perpendicular would be wanted. it would be problematic though trying to get a 12" to 16" inch ring, to accurately move, the exact same distance and keep it level to the cylinder block. would be the challenge.

=============

hhmmmsss, how do i deal with the rods of the cylinders running on this ring. do i simply make a cup, so a ball bearing rides in the cup and then rids on this ring. or do i actually make, a metal roller / wheel and do a grove cut in the cylinder.

a tapered cylindrical shape bearing might work better. enlarges contact area.

===============

===============

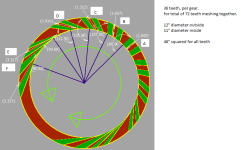

looking at bottom diagram of above picture, and math. a fixed displacement pump might be only way to make room for things. and make it double sided, waved ring, if there was 4 humps, on each side, it would make it a 8 way hyd motor.

putting say a 45 degree angle to cylinders. so cylinder ends point in towards the center. man, that would be tearing the living daylights out of the ring. and warp the ring to up. if not beefed up. though it would help change which direct force was placed on the ring.

then again maybe not. not sure if i could ever get a nice perfect constant wave at any angle beyond cylinders setup at right angles to the waved ring. other words there would be to much variation and the rods of the cylinders would be all over the place. it might be possible. but would end up with using ball bearings. vs being able to use roller wheels or cylindrical shape ball bearings between rods of cylinders and this waved ring. and being at an angle, a ball bearing would more likely want to slide further and end up causing the rod to bend and twist destroying the hyd motor sooner than later.

been trying for a variable displacement hyd motor for the transport wheels, but i just do not see it happening.

bent axial hyd motor. i think i can do, but with a twist. it took a quick spread sheet for miles per hour to inches per minute, wheel circumference, and revolutions per minute. to make the push.

below = a swash plate?!? or rather bent axial pump, and instead of cylinders inside of the bent axial pump running at 45 degrees. thought about letting the cylinders run across humps on a ring.

more humps = slower RPM's.

less humps = higher RPMs,

more humps = a "higher" min RPM

less humps = a "smaller" min RPM

min RPM = amount of RPM that would be needed to keep the wheel spinning. without causing locking up problems. this is a bigger one for me, and possibly getting near "creeper gear" like doings.

more humps = more torque

less humps = less torque

more humps = act like another hyd motor being added in parrallel

1 hump = act like a single hyd motor.

height of the a "wave" errr humps = length of cylinders

distance from peak to peak and GPM (gallons per minute) of hyd oil, and diameter of cylinders and length of cylinders, and amount of them between peak to peak all multiplied by humps on ring = RPM (revolutions per minute)

1 hump = a flat ring, and might as resemble a bent axial pump

2 humps = getting symetrical and applying even pressure to each half

3 humps = i would think, would be min, to basically hold things together. might resemble a planetary gear, with 3 plant gears.

4 plus humps = just adding more torque and reducing RPM's if staying with exact same GPM of hyd oil.

thinking i might be able to use some "plates" with holes/slots put into them to act like valves possibly. so i can switch things around to allow series vs parallel combinations, and in essence gearing. for GPM of hyd oil.

i think i might be able to get away from all gears (spur to planetary) gears completely for transmission like doings, and turn this hyd motor, directly into a rim, or setup that might mimic a electrical wheel motor.

if i keep the humps completely symmetrical, i should be able to "reverse" flow of hyd oil. and get forward and reverse out of this hyd motor. that would mean hyd cylinders would need to be perpendicular to the this waved ring.

==============

hhhmmmssss never really thought about it, changing angle of hyd cylinder to the waved ring. about all that would do is change length of the cylinders, in a fix displacement pump. and change the load points. na.. as cylinders contract, it would be counter productive.

perhaps instead of angling cylinders in line with the ring, perhaps angling the hyd cylinders in towards the center of the ring. na... that would change direction of were power is being transfered to. i would need to "mirror" every cylinder on opposite side of the ring.

================

on other hand, maybe i can make this a variable displacement pump. by some how moving this waved ring further away from the cylinder block. in which case perpendicular would be wanted. it would be problematic though trying to get a 12" to 16" inch ring, to accurately move, the exact same distance and keep it level to the cylinder block. would be the challenge.

=============

hhmmmsss, how do i deal with the rods of the cylinders running on this ring. do i simply make a cup, so a ball bearing rides in the cup and then rids on this ring. or do i actually make, a metal roller / wheel and do a grove cut in the cylinder.

a tapered cylindrical shape bearing might work better. enlarges contact area.

===============

===============

looking at bottom diagram of above picture, and math. a fixed displacement pump might be only way to make room for things. and make it double sided, waved ring, if there was 4 humps, on each side, it would make it a 8 way hyd motor.

putting say a 45 degree angle to cylinders. so cylinder ends point in towards the center. man, that would be tearing the living daylights out of the ring. and warp the ring to up. if not beefed up. though it would help change which direct force was placed on the ring.

then again maybe not. not sure if i could ever get a nice perfect constant wave at any angle beyond cylinders setup at right angles to the waved ring. other words there would be to much variation and the rods of the cylinders would be all over the place. it might be possible. but would end up with using ball bearings. vs being able to use roller wheels or cylindrical shape ball bearings between rods of cylinders and this waved ring. and being at an angle, a ball bearing would more likely want to slide further and end up causing the rod to bend and twist destroying the hyd motor sooner than later.