Andy,

Drum brakes should fine but disc look cooler. Another thing you could do is run pinion brakes. I think it should function good without welding the center diff. With having your independent brakes front and rear you can transfer the power to the front or rear. If you weld it it may tear up the grass a little when you turn. I did not know how much snow you got, I was just curious if you where going to have any other attachments. Keep the pictures coming and Keep up the good work.:thumbsup: Do you have a long mowing season?

lol l agree discs look cooler but with such deep dish wheels the drums will never be seen again, l think having the handbrake already built in is enough reason for the drums to stay, sure l could fit some discs of the rear of a car so as l have a handbrake but it seems a lot of work for no gain

well normally we dont get much snow but who knows whats in store,

this year has been all screwed up we started with warnings of drought and water shortages as we have had 2 winters with below average rain fall, and then the heavens opened 6 months ago and it hasent stopped raining since.

some weeks we get a years rainfall, crops are rotting in the fields all over the uk, if this level of rain continues into the winter months then we will have some proper snow

l would like to make as many attachments as l can find a use for, certainly a driven brush for the front, and a big flail, maybe buy some thing like this that wants repairs and make a new deck for it

Flail Mower/Topper. 5'6" cut. Restoration Project. | eBay

we have a reasonably long cutting season and could be longer if it wasent so wet before and after it, and during it now lol,

part of the reason for the for the wide wheels was to let me get out on the ground earlier and later in the season while its wet without causing to much damage to the ground,

l dont have a commercial use for the mower its just for my own use, l have a buggy track l have mown out and like to keep it cut short, you can see the track l want to use this mower on in this vid from much earlier in the season, was wet then as well

gopro on bonnet - YouTube

gopro on bonnet - YouTube

l sectioned off 4 or 5 acres at the bottom of the main field and each year l plant a few hundred trees around the track, one day it will be a wood lol, l have also been working on a pond/lake as and when l can afford diesel for the excavator :laughing:

l will get some upto date vid next week as the rain is forecast to run out, grass and trees are much taller now

edit: found a better vid showing the area l want to use the mower on, camera mount fails halfway through and drops off though

http://www.youtube.com/watch?v=DmMGUCmSPQ4&feature=plcp

http://www.youtube.com/watch?v=DmMGUCmSPQ4&feature=plcp

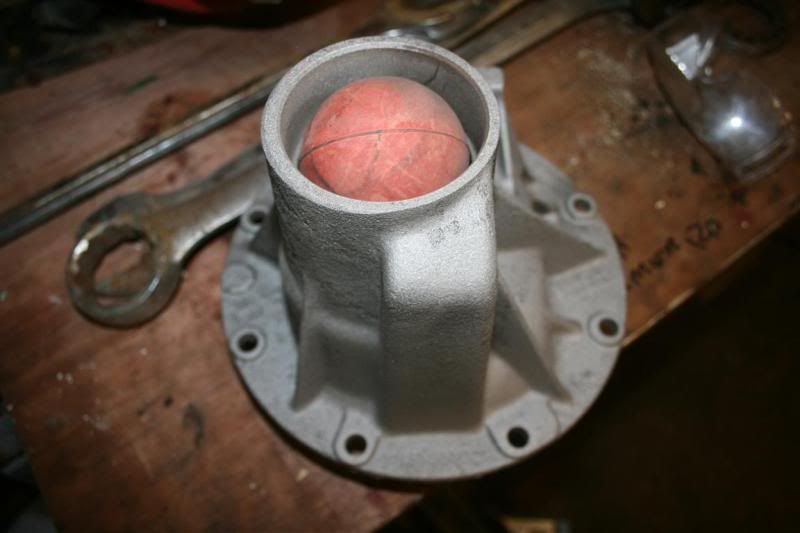

![buggybuild191[1].jpg buggybuild191[1].jpg](https://www.tractorbynet.com/forums/data/attachments/269/269466-e888cbfa9aa26ea23f35bb3de29e4817.jpg)