Shield Arc

Super Member

I really never paid any attention to the Everlast brand of welders, until reading some of Mark's post here. I was so impressed with his knowledge of welding I clicked on his user name, and went to the Everlast web site. Did a little reading, then asked Mark a few question in some post here. After thinking about it a few days I called Mark and had a long conversation with him about welding. I bought this welder for the Hot Start option. When striking an arc the machine automatically gives you a little more power, less sticking of the rod when starting. This machine also has an automatic arc force / dig, which helps with not sticking the rod also when welding. The machine also has a separate welding lead port for 6010, you plug the ground / work lead into this port. I'm not going to set here and tell you the arc compares to my mid 50's shorthood, but I will tell you the arc with 6010 is better than my $6,000.00 Dynasty 300! I was very impressed with this little machine with 7018. One of the nicest 7018 arcs I've ever ran! Another thing I really like is the cooling fan, it stays on all the time. I've had my Dynasty 300 for over 4-years, and I still can't get use to the "Fan on Demand"!

For $350.00 I'm very impressed with this little machine!:thumbsup:

Yeah that's right, a welding glove setting on top of it.:laughing:

6010.

6010 root pass on 2 inch pipe.

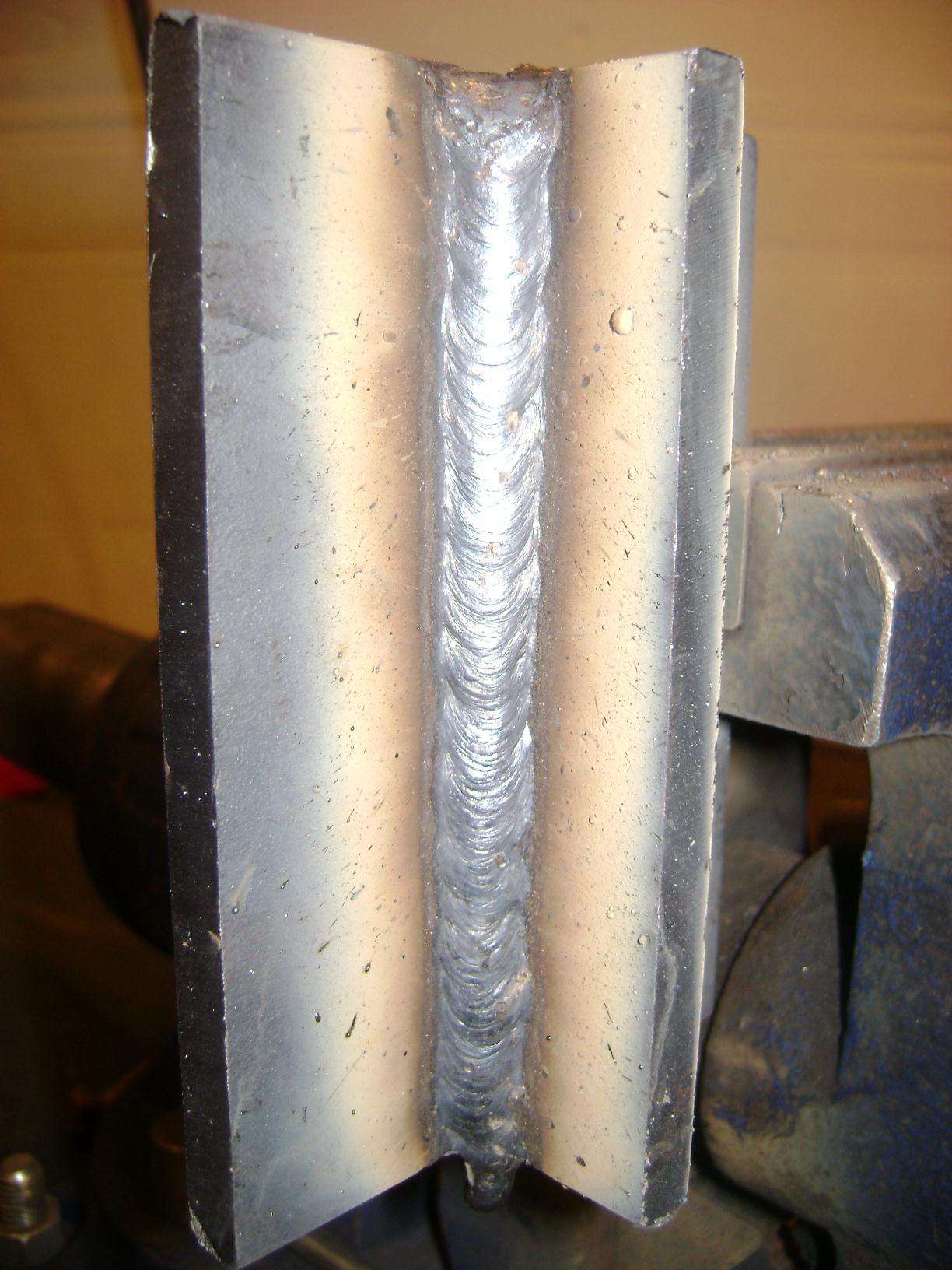

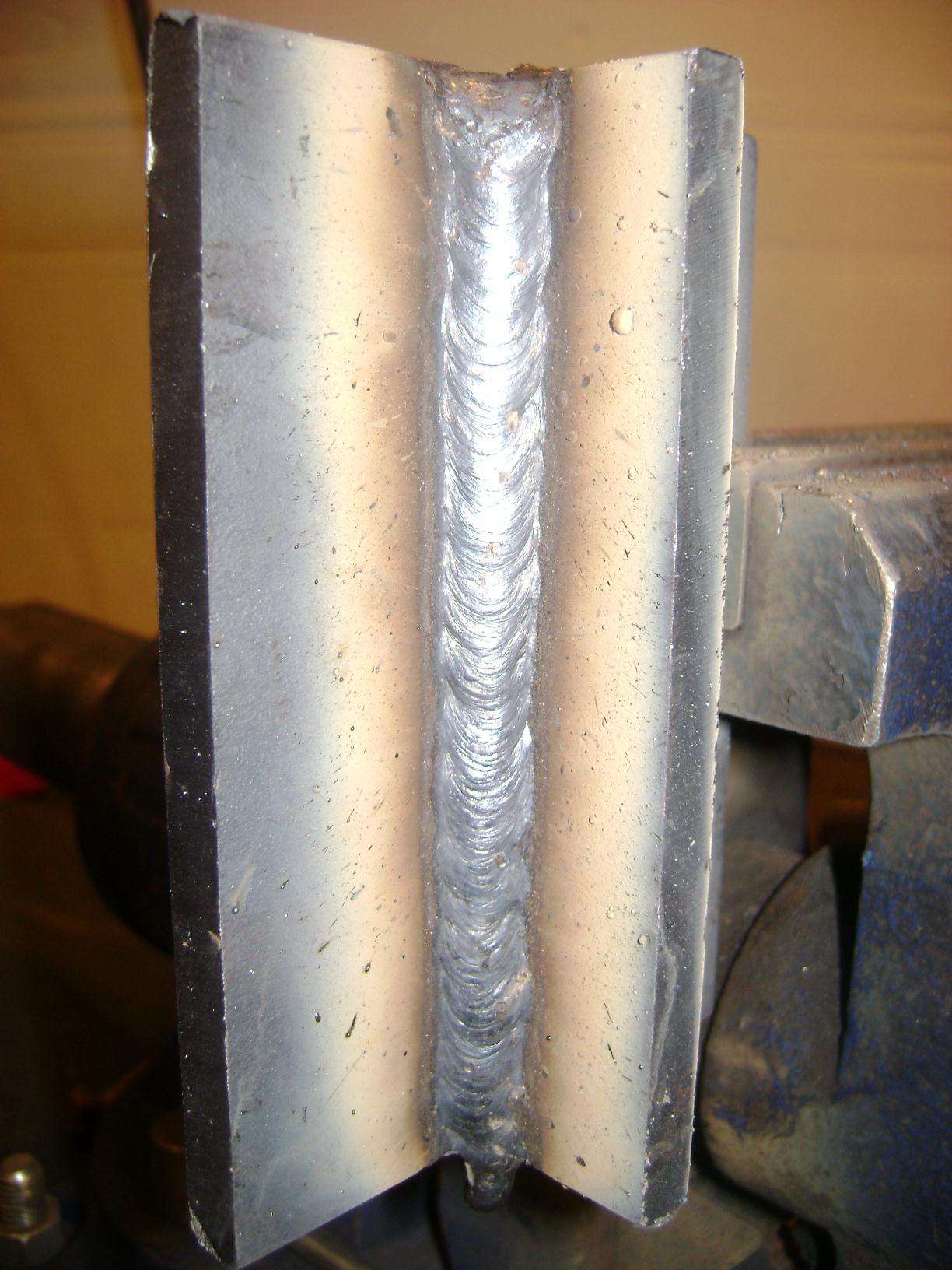

7018 vertical uphill.

For $350.00 I'm very impressed with this little machine!:thumbsup:

Yeah that's right, a welding glove setting on top of it.:laughing:

6010.

6010 root pass on 2 inch pipe.

7018 vertical uphill.