garnet

Bronze Member

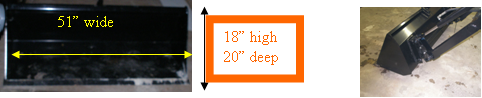

Hi guys, the pictures you see are of my loader. Not too bad, if I do say so myself .But you know what they say - 20/20 vision is best in hind sight. As you browse through my work I will critic it for design flaws that I feel could be improved upon. Your input would be greatly appreciated. This site is teeming with a lot of talented and brilliant people.

Excuse me if I seem to be stating the obvious at times, I’m also doing this as documentation for my four sons.

Excuse me if I seem to be stating the obvious at times, I’m also doing this as documentation for my four sons.

Last edited: