bmaverick

Super Member

- Joined

- Sep 17, 2013

- Messages

- 6,887

- Location

- Beloit-WI

- Tractor

- Yanmar YM2610 ■YANMAR GURU■ EXTRAORDINAIRE

Since the lower sway arms for implement attachment are not OE and longer than normal, I would recommend upgrading those sway chains to this set.luckily i was able to devote some time to it and finish up installing the lower arm anchors.. i have decided to keep the lift arms as bolts with shims to ensure everything stays aligned and tight.

i pulled both of the old side mounts off and noticed someone had drilled and tapped the left side out to a 1/2 inch bolt instead of it using M10x1.5 so it went from a easy swap to a lets dig in a little deeper kind of day.

i noticed when i pulled the left side off, that the bolts seemed pretty short, so i inspected them a little closer and discovered that the original installer of the old side plates used short bolts and only tapped the outer housing (the bolts being used for the side plates are actually the bolts that hold the outer axle housing on to the differential case.

they did drill deeper, but didnt tap it. so i drilled it to full depth and tapped it to 1/2-13 as that is what was already tapped into the outside covers. long story short i installed both sides and think it looks pretty good, and it feels exceedingly solid, being that the bracket is resting against the cutout in the frame, as well as the pin extends into the frame.

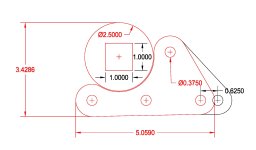

i designed the plates so that the back edge would be flush with the back of the tractor. i am toying with the idea of cutting a plate that would bolt on to the back of the differential where the tiller attachment used to be, and would also bolt to each of the side plates.

i made the side plates out of 3/4 inch steel. this way if i see any deflection i can make up that back plate and bolt it on without too much issue.

Stabilizer Chain (each)

You will need some sort of turn-buckle to properly fit and control sway of various implements.

Mount to the farthest out hole on those lower arms and back to those hook-ups near the axle.

The present chains you have are like a kids swing set, ready to snap at the first jolt.

The last thing you need is a tractor implement acting like a tail-that-wags-the-dog effect. If this happens severely, the tractor better have a ROPS as roll-over is likely. Sway control is a priority with a 3-point.