electrycmonk

Silver Member

- Joined

- Nov 6, 2018

- Messages

- 212

- Location

- Near Denton, TX

- Tractor

- Satoh 370 diesel & Cub Cadet 7260 Diesel 4WD standard

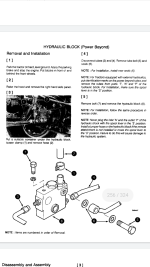

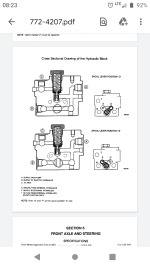

The joystick is directly connected to the cast iron FEL directional control valve inside the "black box" mounted to the FEL frame post.The FEL valve is the valve that is controlled by the joystick you use to operate the FEL. Not sure the Cub is built but flow the linkage from the joystick down to where it connects to the FEL directional control valve. This valve body is typically cast iron and would normally have seven lines connected to it for an open center system.

Lines are:

inlet or pressure

two lines for raise and lower of loader

two lines for curl and dump

one tank line going back to tank

one power beyond line that would typically power the 3 point hitch.

Quick test to see if your cub is plumbed this way is to lower the 3 point fully. Then operate a function on the loader fully like curl or dump and attempt to raise 3 point at the same time. If 3 point does not move when the bucket is moving you have power beyond from the FEL to the 3 point. You will have to identify this line to build a connection for the back hoe.

FEL joystick will raise/lower or curl the bucket as a solo function at a reasonable speed.

FEL joystick will slow to a crawl is I raise/lower AND curl the bucket in OR out. If I keep curling and STOP the raise/lower then the curl jumps to it's normal speed of movement

I [just tried the FEL single function AND 3-point raise at the same time....no 3-point movement on every test. ]

[Edit part 2= I tested drop 3-pt simoltaniously w/FEL movement and it would drop while FEL is moving

/End edit

I do know that Either the FEL or the 3-PT will cause the system typical sound effect of a squealing belt for a couple nano-seconds when the motion has reached it's maximum R.O.M.(range of motion) then it's shuts off and is silent. This sound I have known about since I started to learn tractor safety in 4H in Calhoun County, Michigan growing up on/around a Holstein farm- initially; then helping Grampa in So-Cal with the stump grinders.

Last edited: