kdwellssr

New member

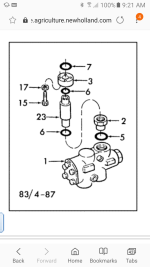

Depends on what you have tried. The original "O" rings are not plain O rings and are not normal sized. If you go to the tractor dealer there are two O rings have different part numbers for two different tractors of the same model series. Getting the wrong O ring will make it blow again. I ended up getting both of them because I didn't know which one I had and it is a 60 mile round trip to get there. Also make sure there is no water in the hydraulic oil as that will change the oil viscosity and the O rings ability to withstand the pressure. Purchasing the proper O ring will make a big difference. If that doesn't work. Make sure the engine mount are not at all loose. The valve is mounted to the frame and the twisting of the engine can cause the O ring to blow. Next "what I've done". I went to the hydraulic repair shop and had it checked to be sure the grooves were not damaged. Then I went on line and ordered some O rings that are metric...since the tractor was not made in USA. The ring size that I purchased is :2.4mmX13.8MM Buna-N-90. So far they have been in place for 1 year. I've used front bucket to pick up some items heavy enough that it couldn't life it and they are till in tact. Hope this helps you. Next plan was to make a adapter so the valve is not a direct fit to the pump... via hydraulic hose and offsetting valve. So far not going to have to try that.