Tim Berframe

Bronze Member

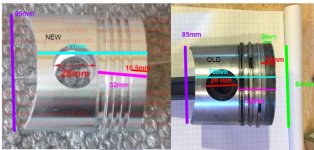

I have a 2007 Yangdong Y485. Head gasket will not seal. I have compression in the water. I measure the liner protrusion to be 36 thou above the deck. All liners are in plane with each other. The deck is flat. The head surface is flat.

I cannot find a spec for this engine ( Cat and Perkins and others all seem to be less than 10 thou). Perhaps one of the dealers on here might know? With such a huge protrusion, it seem doubtful to me that the skinny gasket will seal?

I cannot find a spec for this engine ( Cat and Perkins and others all seem to be less than 10 thou). Perhaps one of the dealers on here might know? With such a huge protrusion, it seem doubtful to me that the skinny gasket will seal?