Too much stress on the part for a weld. This is one of those time to buy new.

how do you think they make those parts? They weld them.

Too much stress on the part for a weld. This is one of those time to buy new.

Got it welded! :thumbsup:

Our friend had no problems with it. When he put the parts together they way they broke, it lined itself right up because there were a couple small "protrusions" that fit in the corresponding depression just like plugging it into a socket.

He then tacked it in place and did as was suggested with grinding the beveled space in between the two pieces. He welded from inside to out then cut the tacks and ground that area and finished the deep welds. When he had it sufficiently built up he did a continuous bead around the entire rod.

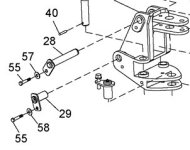

I took a picture of the cylinder back on the tractor. It works just like new.

View attachment 264470

Got it welded! :thumbsup:

Our friend had no problems with it. When he put the parts together they way they broke, it lined itself right up because there were a couple small "protrusions" that fit in the corresponding depression just like plugging it into a socket.

He then tacked it in place and did as was suggested with grinding the beveled space in between the two pieces. He welded from inside to out then cut the tacks and ground that area and finished the deep welds. When he had it sufficiently built up he did a continuous bead around the entire rod.

I took a picture of the cylinder back on the tractor. It works just like new.

View attachment 264470

as explained it wasn't the case here, but....Because just normal digging, that cylinder and weld is under compression. And it looks to me that in order to break that weld, it had to be under tension. Not saying you are doing anything wrong. Just wondering how it broke is all.