You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

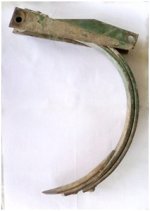

Two layer cultivator shank

- Thread starter omidlolo

- Start date

- Views: 4576

More options

Who Replied?

/ Two layer cultivator shank

#1

Allows more flex or spring.

Inner layer is under tension, and the outer layer is under pressure in actual.

are two layers material different?

kevin37b

Veteran Member

That looks more like chisel plow shank , runs deeper than a cultivator . Actually 2 layers stiffen it up alittle and still allow some flex .

plz specify your comment source? im need sources.

where i can find technical (Engineering) information about it?

ex. design parameter or formula!

extra from http://www.industriehof.com/katalog/kategorie/2747?lang=en

Can i use the leaf springs relations for it?

where i can find technical (Engineering) information about it?

ex. design parameter or formula!

extra from http://www.industriehof.com/katalog/kategorie/2747?lang=en

Can i use the leaf springs relations for it?

Last edited:

MHarryE

Elite Member

- Joined

- Feb 15, 2009

- Messages

- 2,980

- Location

- Northeastern Minnesota

- Tractor

- Kubota M7-171, M5-111, SVL75-2, RTV900XT & GR2120; CaseIH 1680 combine

Bending stiffness is equivalent to the modulus of elasticity and the moment of inertia. In the case of the flat bar which is the actual cross section of each cultivator shank at any point, the moment of inertia is width x thickness cubed / 12 (English measures). If it was a single beam for example 1 inch by 1 inch for easy calculations, I = (1 x 1)/12 or 1/12. In this case you have 2 beams each 0.5 thick. The cube of 0.5 is 0.125 so each beam has a moment of inertia of .125/12, but you have 2 independent beams stacked so it is additive or 0.25/12. The formula is M=EIk where M is the bending moment, E is the modulus of elasticity for the material being used, and I is the area moment of inertia. k is the resulting curvature. Two thicknesses stacked together are 1/4 as rigid as 1 single thickness unless they are completely fused for the entire length.

why 1/4?Bending stiffness is equivalent to the modulus of elasticity and the moment of inertia. In the case of the flat bar which is the actual cross section of each cultivator shank at any point, the moment of inertia is width x thickness cubed / 12 (English measures). If it was a single beam for example 1 inch by 1 inch for easy calculations, I = (1 x 1)/12 or 1/12. In this case you have 2 beams each 0.5 thick. The cube of 0.5 is 0.125 so each beam has a moment of inertia of .125/12, but you have 2 independent beams stacked so it is additive or 0.25/12. The formula is M=EIk where M is the bending moment, E is the modulus of elasticity for the material being used, and I is the area moment of inertia. k is the resulting curvature. Two thicknesses stacked together are 1/4 as rigid as 1 single thickness unless they are completely fused for the entire length.

mikehaugen

Elite Member

Bending stiffness is equivalent to the modulus of elasticity and the moment of inertia. In the case of the flat bar which is the actual cross section of each cultivator shank at any point, the moment of inertia is width x thickness cubed / 12 (English measures). If it was a single beam for example 1 inch by 1 inch for easy calculations, I = (1 x 1)/12 or 1/12. In this case you have 2 beams each 0.5 thick. The cube of 0.5 is 0.125 so each beam has a moment of inertia of .125/12, but you have 2 independent beams stacked so it is additive or 0.25/12. The formula is M=EIk where M is the bending moment, E is the modulus of elasticity for the material being used, and I is the area moment of inertia. k is the resulting curvature. Two thicknesses stacked together are 1/4 as rigid as 1 single thickness unless they are completely fused for the entire length.

Excellent explaination, I was not aware of this formula. I will have to retain this for future reference.

D7E

Veteran Member

- Joined

- May 10, 2006

- Messages

- 2,267

- Location

- manitoba

- Tractor

- Versatile 895 Versatile 876 Ford TW20 Ford TW5 MF 3505 FWA MF 390 FWA Ford 7600 Fiat 766 FWA JD 2030 MF 165 MF 35 Fordson major x 3 CAT 416 b Backhoe Case 580 b backhoe MF

plz specify your comment source? im need sources.

where i can find technical (Engineering) information about it?

ex. design parameter or formula!

extra from Industriehof Scherenbostel Cultivator parts to fit adaptable for Ventzki

Can i use the leaf springs relations for it?

My source is decades of staring back at the **** things for 16 hours a day nothing quite as technical as the info from these guys

MHarryE

Elite Member

- Joined

- Feb 15, 2009

- Messages

- 2,980

- Location

- Northeastern Minnesota

- Tractor

- Kubota M7-171, M5-111, SVL75-2, RTV900XT & GR2120; CaseIH 1680 combine

why 1/4?

It's from the calculation. One cubed is one. One half cubed is one eighth. Double one eighth (two thicknesses) and you get one quarter. It's the same way with typical leaf springs (not the single leaf the Chevy Nova used). Stacking thinner layers results in a lower spring rate or softer ride than one heavy leaf. I am not sure about the cultivator shank but I believe they use multiple leafs to get more action out of the shank therefore breaking up the soil better. I have an old cultivator with single thick shanks but then a triple large coil just before it clamps to the frame to give it ground busting action but the shanks were expensive to break. They aren't expensive anymore because the company (Case) realized it was a bad design and quit making it, and service parts, long ago. I pulled it out of a fence row to use for some special jobs where I need a small cultivator.

Here are some similar links:

- Replies

- 18

- Views

- 7K

- Replies

- 0

- Views

- 1K