Thanks for your comments thus far. To clarify some points I have uploaded additional photos. 1st photo shows left side to reveal the size of the draw pin hole in the Land Pride RCR1260 mower. 2nd shows the right hand side pin as it was installed by the factory (or the dealer?) and it's never worked loose nor has it ever been removed. 3rd photo shows side view of the right pin to detail the lack of clearance for a bushing. All photos in this batch are with the 3-point hitch raised up with the mower fully suspended.

1) The flat washer is required, because the draw pin hole in the Land Pride mower is so big that the lock washer alone would be swallowed up by it.

2) The Quick Hitch is a Speeco Cat 1 E-Hitch, and based on photos of the product on the site where I bought it, it's designed this way. Design flaw? There's no room for a bushing as the quick hitch is designed specifically for Cat-1 pins.

3) If wobbling of the pin is working it loose due to suspected design flaw in the Quick Hitch, why has the right pin never wiggled loose?

At this point I'm leaning toward going with the castle nut and cotter pin, loctite and torqued on with an impact hammer.

Thanks again for your analysis and comments.

-Mark

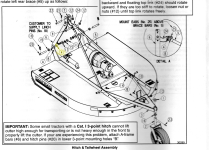

Edit to add: Checked the manual and confirmed, I'm missing a bushing (part #4 on manual scan I just uploaded) around the threaded portion of the pin.