Big Barn

Super Member

- Joined

- Aug 20, 2013

- Messages

- 7,047

- Location

- Victoria, B C

- Tractor

- More than 40 over the years. Ten at any one time. Mostly Ford and New Holland

I wish there was a similar sand blasting facility around here. I have been all over the S East and dont think I have ever seen such a facility that would rent the baster and a place to work. Seen plenty of large blasting businesses, but no diy places.

I have one of those small blasting cabinets to glass bead small parts, I dont have the cfms to to do any big blasting projects.

We have one of those DIY blast shops that opened up two or three years ago. They had good reviews and customers seemed to like the atmosphere and experienced support.

I decided to drop in and check it out for a project I had in mind. It was located in a semi industrial part of town with the 3 or 4 dedicated parking spots in front of their shop occupied. On street parking was minimal in a neighbourhood known for hookers and drug dealers.

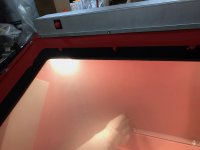

Since I couldn't even find a spot to park I couldn't really see a future for me there. I ordered my own blast cabinet that week.

Terry