downsizingnow48

Elite Member

I use a 2x72 belt grinder a lot, it is very versatile and powerful. I decided to make a sliding work table to improve accuracy on some operations.

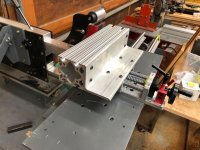

Photo 1 - this is the fixed work rest I made when I first got the grinder. 1/2" aluminum. It is much larger than what is normally used but handy for many things.

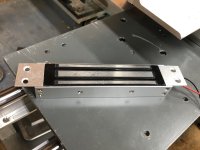

Photo 2 - I installed 20mm rails and linear bearings for the slide mechanism.

Photo 3 - the work table is 3/8" aluminum. I put a grid of threaded 5/16" holes so standard milling machine hold-downs can be used on large or irregular work pieces. It is also drilled to accept a sliding T-nut extrusion.

Photo 4 - T nut extrusion installed. I am making a long bread slicer knife from a power hack saw blade. It is fixed to the extrusion with three clamps made from 1/4" steel.

With this setup it is easy to get a perfect bevel on the 20" knife blade. As well as perfectly square and even finishes on other workpieces.

The 2x72 grinder works well enough that I sold my Baldor wheel grinder which I never touched after getting the belt grinder.

Photo 1 - this is the fixed work rest I made when I first got the grinder. 1/2" aluminum. It is much larger than what is normally used but handy for many things.

Photo 2 - I installed 20mm rails and linear bearings for the slide mechanism.

Photo 3 - the work table is 3/8" aluminum. I put a grid of threaded 5/16" holes so standard milling machine hold-downs can be used on large or irregular work pieces. It is also drilled to accept a sliding T-nut extrusion.

Photo 4 - T nut extrusion installed. I am making a long bread slicer knife from a power hack saw blade. It is fixed to the extrusion with three clamps made from 1/4" steel.

With this setup it is easy to get a perfect bevel on the 20" knife blade. As well as perfectly square and even finishes on other workpieces.

The 2x72 grinder works well enough that I sold my Baldor wheel grinder which I never touched after getting the belt grinder.