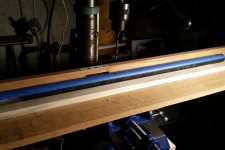

I have a 6' long table I made for my drill press years ago for a woodworking project that supported the pipe. There's a piece of 2x4 in the middle that secures it in the drill press vice. I ran a length of blue painter's tape on the pipe and marked my 8" spacing. I then drilled one 5/16" hole and secured the pipe to a piece of 3/4" poplar with a screw. This kept the pipe from rotating so all the holes would be lined up. I just slid the pipe attached to the 3/4" board on the table drilling a the 5/16" holes first and then went back and drill the 1/2" holes. Last hole one I removed the screw and drill it to 1/2".

Here's a picture of it...

View attachment 527094

The tine spacing isn't that critical, where if the hole is off a 1/16" or even 1/8", it's not going to affect it's performance. The key is keeping all the holes parallel. That's where screwing the pipe to the 3/4" board helps to maintain the proper pipe position.