You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scale Cat Twenty Two Dozer Ride On For My Son

- Thread starter dozerbuilder01

- Start date

- Views: 158984

More options

Who Replied?

/ Scale Cat Twenty Two Dozer Ride On For My Son

#141

philbuilt

Gold Member

Corel is a PITA but I started with it at 2.0 . Just remember to convert to curves prior to export to vectorization and you should be good.

Convert to curves to vectorization. Then export

OP

dozerbuilder01

Bronze Member

- Joined

- Jan 13, 2012

- Messages

- 66

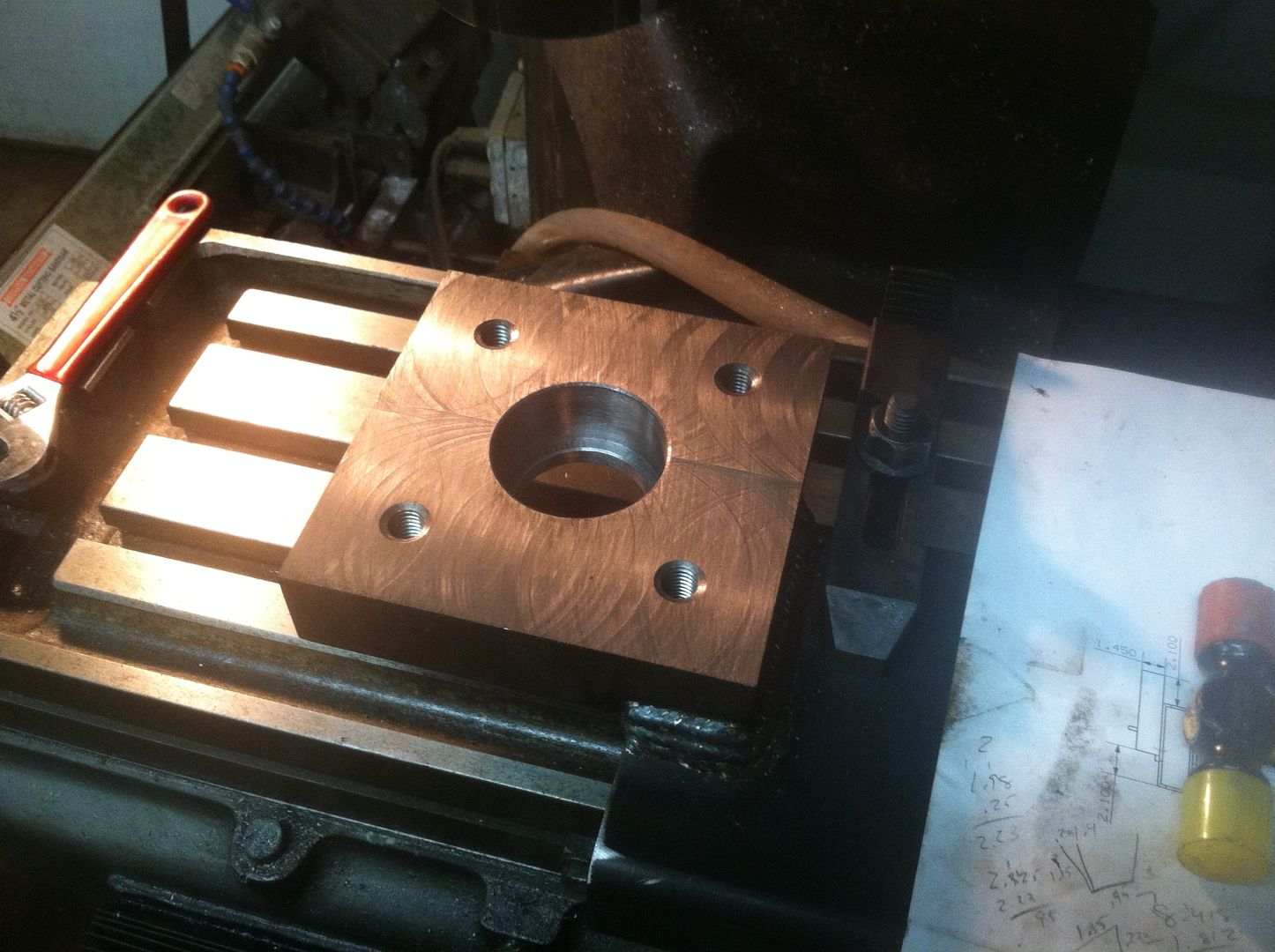

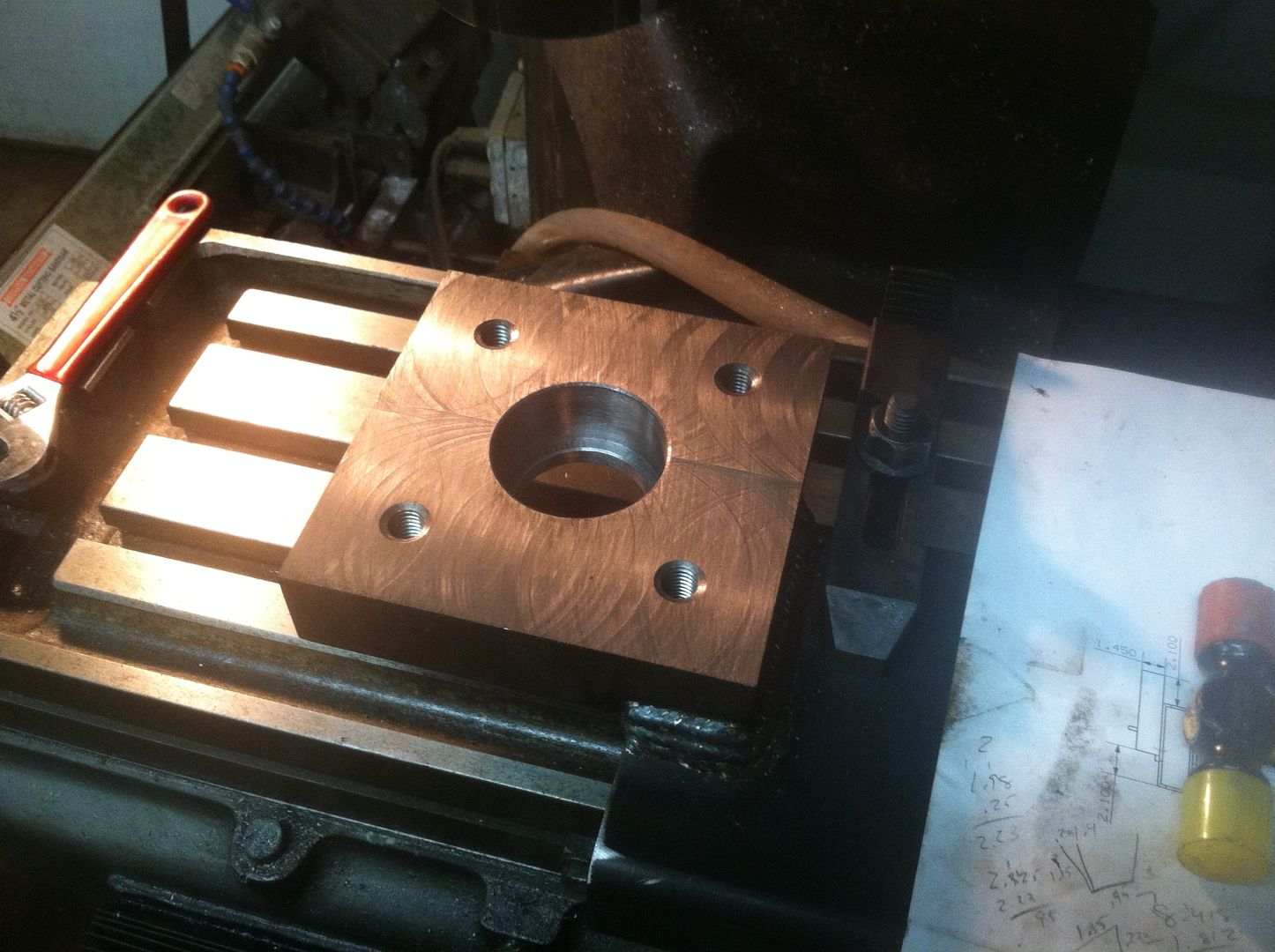

Finished machining the motor mount block.

Welded on the tensioner rails. I need to clean off my welding table.

Welded on the tensioner rails. I need to clean off my welding table.

Last edited:

whistlepig

Elite Member

I am enjoying your posts. No doubt that you are a machinist.

OP

dozerbuilder01

Bronze Member

- Joined

- Jan 13, 2012

- Messages

- 66

I am enjoying your posts. No doubt that you are a machinist.

Weird part is....I'm not. But I like the challenge and I like to learn.

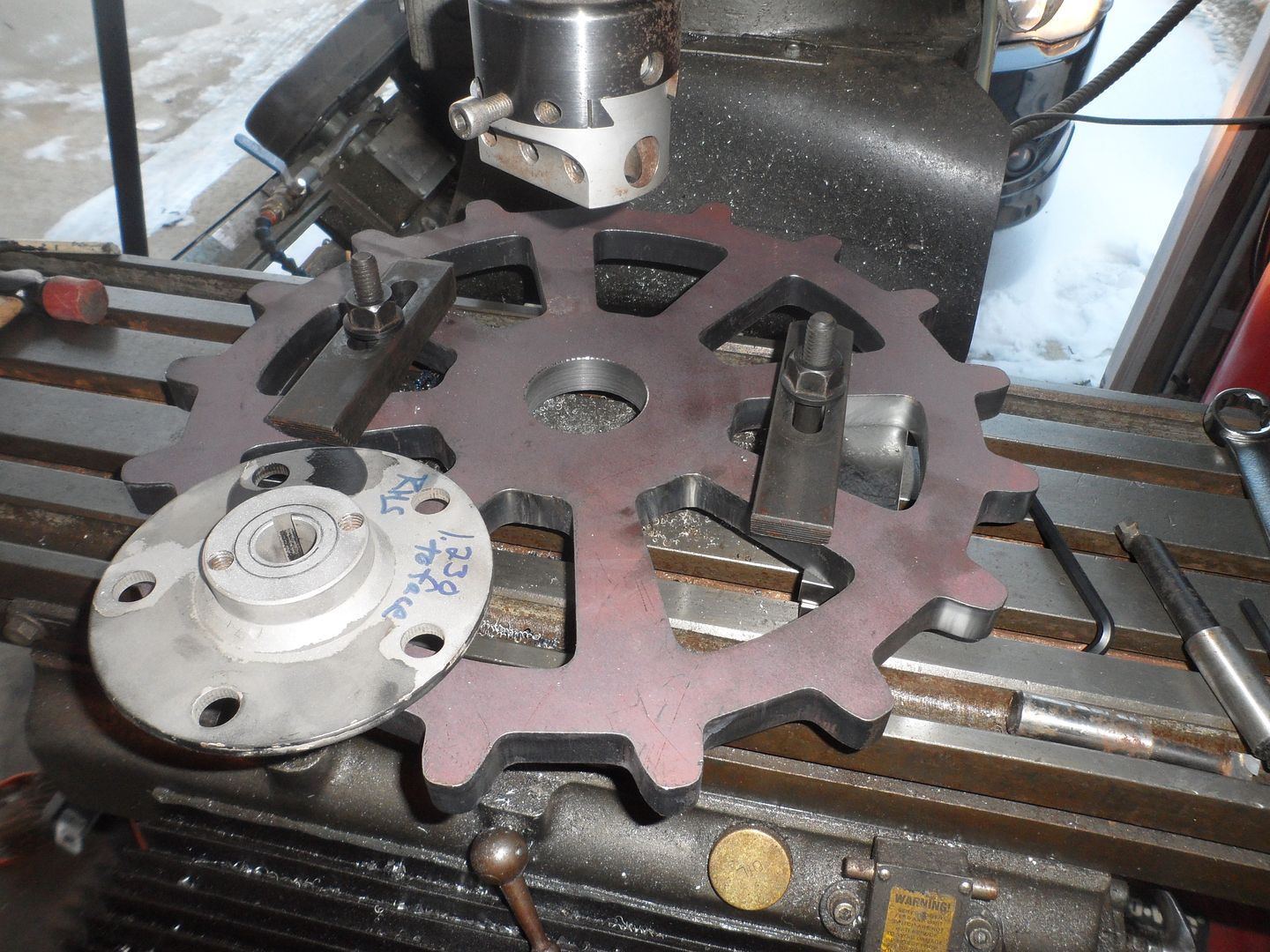

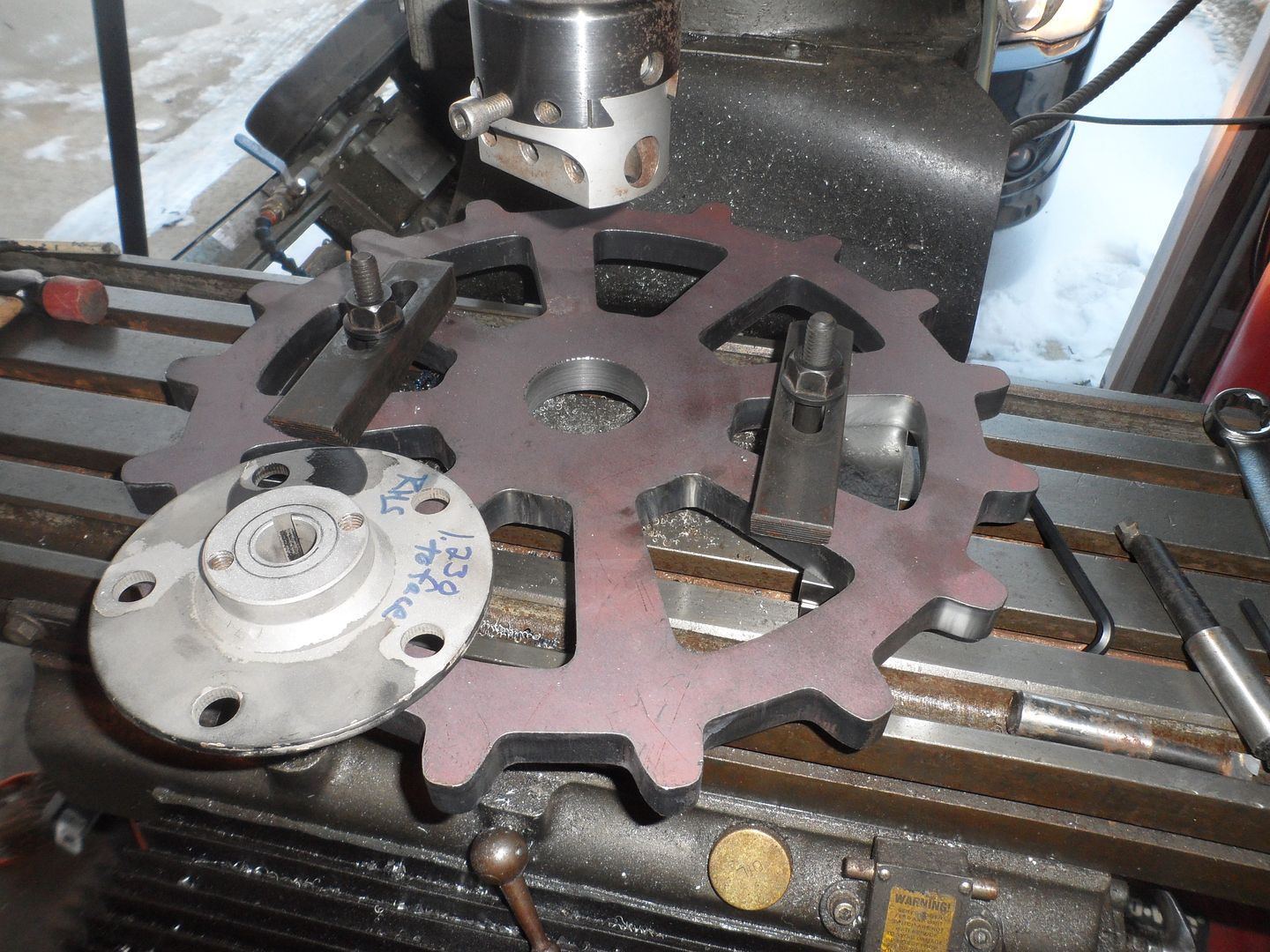

So I'm not wasting anytime on the new sprockets.

Had to finish machine the bore. The sprocket will rest on that instead of relying on the bolts. This will keep it centered and transfer the weight directly to the spindle of the motor.

Then drilled the 5 bolt pattern

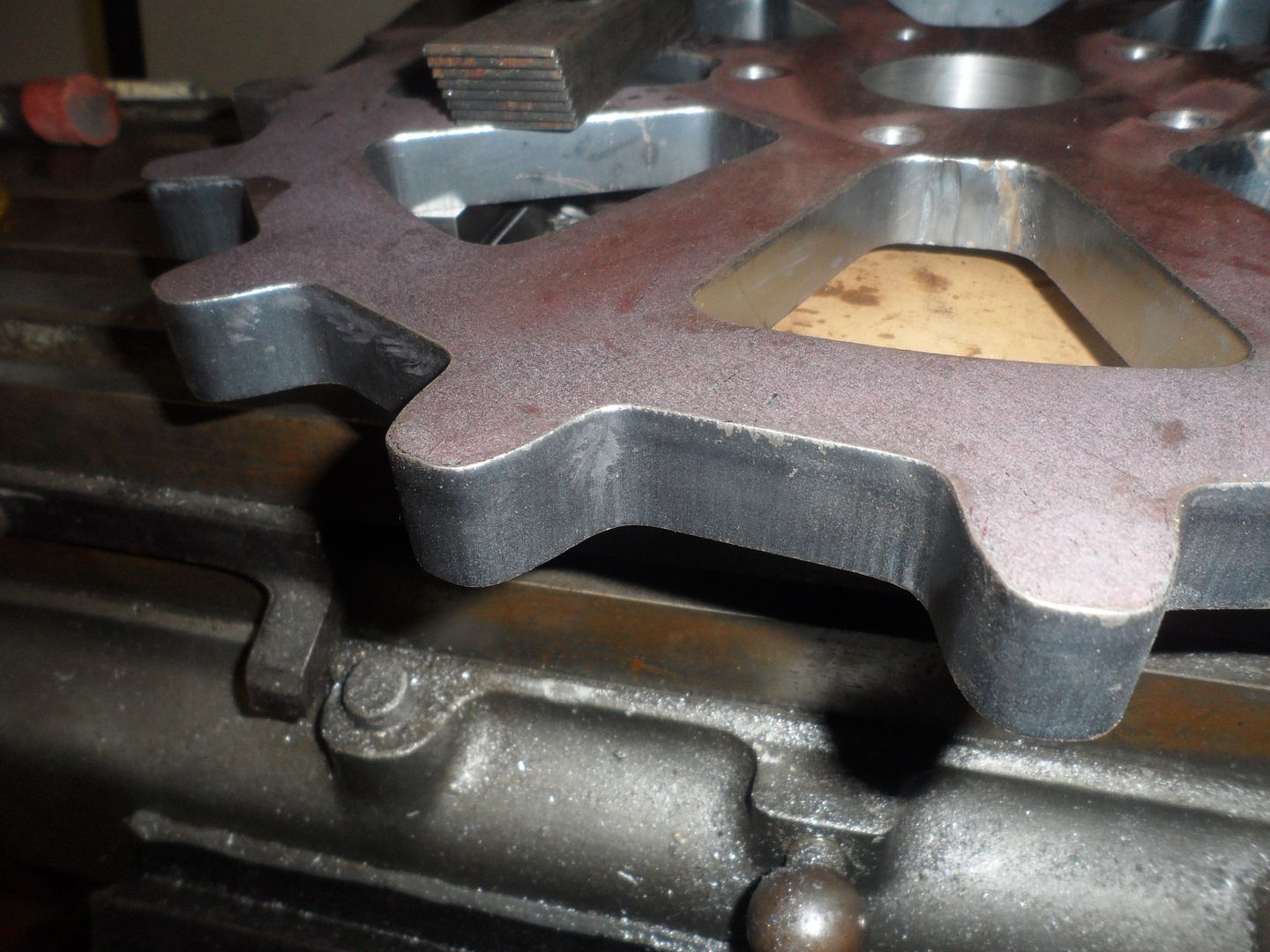

Now I have to mount the rotary table and machine a 1/8" recess to clear the hub flange. Need to do this because of stack up issues. Hard to explain. Remember, I got these hubs from the old transmission. So I had to work with what I got. And I also need to cut a chamfer to clear the weld between the hub and the hub flange.

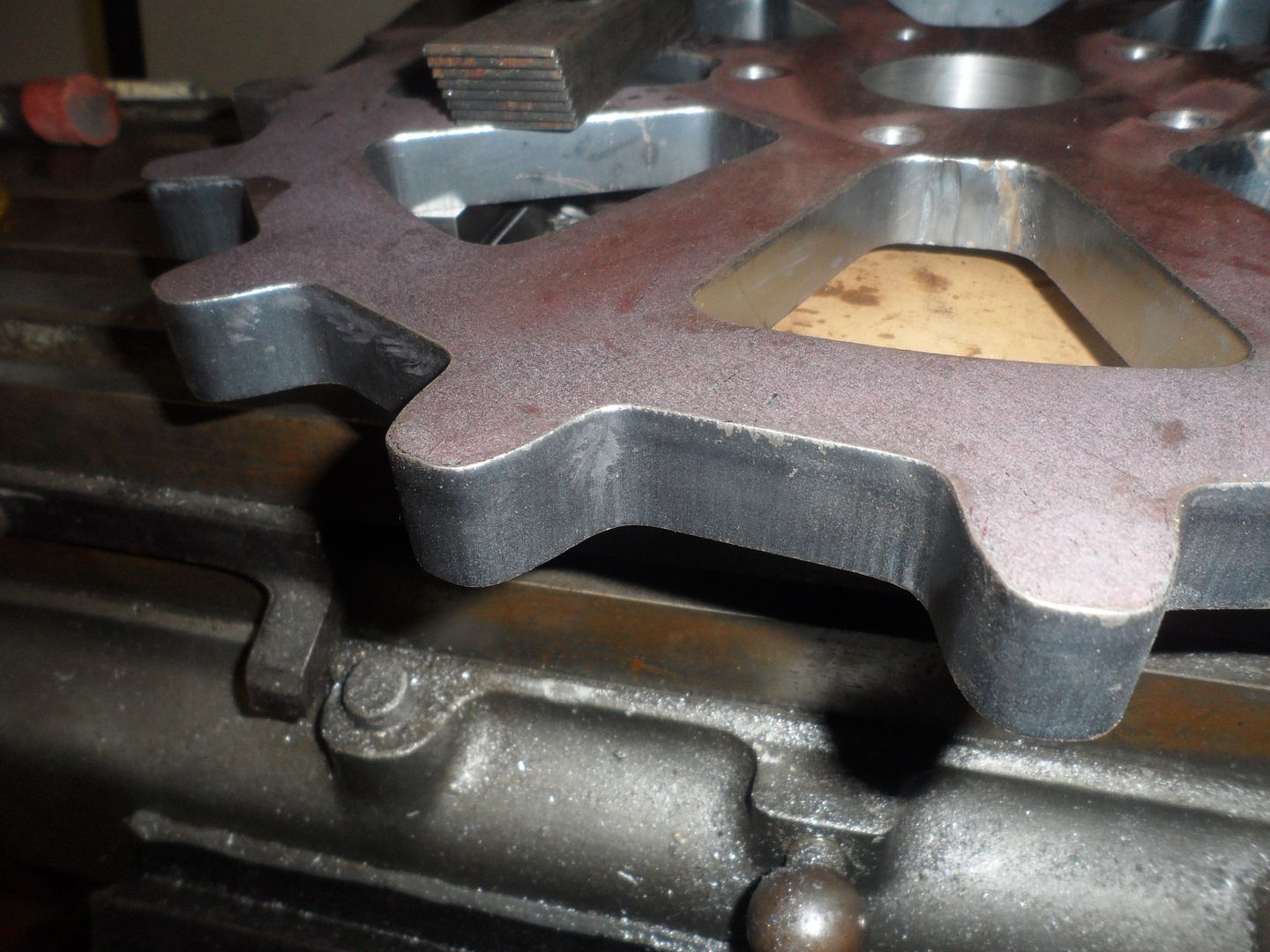

Here is a close up of the cut.

That's from a plasma cutter.

strum456

Platinum Member

I just noticed this thread. WOW! The best part about this will be the life-long lesson you will have taught your son. From watching and helping my dad around the farm, I learned that with enough time and money, I can figure out how to fix or build just about anything. I decided to become a teacher so I could try to pass this on to any student that will listen. It is unfortunate, but father/son projects are extremely rare these days. When I get to talking with my students about tools and projects, 90% of the time the students mention their grandparents first. I can only assume this is because these skills are not being passed down. Way to go man!

Considering the meticulous attention to detail and heavy-duty nature of this project, I have to ask: What's the deal with that engine? Are you planning for such deep gear reduction that a larger engine would not be needed? I think a 3 cyl diesel would be really nice on there :thumbsup:

Considering the meticulous attention to detail and heavy-duty nature of this project, I have to ask: What's the deal with that engine? Are you planning for such deep gear reduction that a larger engine would not be needed? I think a 3 cyl diesel would be really nice on there :thumbsup:

Alien

Elite Member

Geez.. don't give him ideas. He changes it enough as it is... lol

OP

dozerbuilder01

Bronze Member

- Joined

- Jan 13, 2012

- Messages

- 66

I just noticed this thread. WOW! The best part about this will be the life-long lesson you will have taught your son. From watching and helping my dad around the farm, I learned that with enough time and money, I can figure out how to fix or build just about anything. I decided to become a teacher so I could try to pass this on to any student that will listen. It is unfortunate, but father/son projects are extremely rare these days. When I get to talking with my students about tools and projects, 90% of the time the students mention their grandparents first. I can only assume this is because these skills are not being passed down. Way to go man!

Considering the meticulous attention to detail and heavy-duty nature of this project, I have to ask: What's the deal with that engine? Are you planning for such deep gear reduction that a larger engine would not be needed? I think a 3 cyl diesel would be really nice on there :thumbsup:

That's true these days. Seems that almost anything can be bought so why make it. And a lot of people just don't care to fix anything because replacements are so cheap. I fixed a 40" LCD tv two years ago ($4 worth of capacitors) and my fridge a few months ago ($20 for a thermistor and cover) all by googling it. And just trying. I really had nothing to lose.

Well, I got a good deal on the engine at the time. The mower with the old transmissions (that I no longer have) had a 18hp twin cylinder engine which is too big physically for the dozer. The mower was 2,200 lbs and ran 3 blades. My dozer was going to weigh less than half that. And not run mower blades. So I guessed that 12.5hp was enough. Now that I have new pumps, I was able to find the spec sheets. A quick glance looks like I should get 140 ft-lbs of torque from each side. I'm going to get the setup running and I'll take a closer look at the curves. I may spring for a 15hp Kohler. We'll see. Diesel would be fun but that would be even more money that I don't have and a 3 cyl would be way too big. The sound would be cool though.

Geez.. don't give him ideas. He changes it enough as it is... lol

This change would be simple. I promise. No more changes after that.

Haven't taken many pictures. Just been going to town on different parts.

Had to machine the sprocket for the hub. It sets in by about an 1/8" (because of stack up issues). And had to cut a chamfer for the weld.

Almost finished the second frame rail. Just a few small things to do.

It should be sitting on tracks by early April.

That is all.

whistlepig

Elite Member

Weird part is....I'm not. But I like the challenge and I like to learn.

So I'm not wasting anytime on the new sprockets.

Had to finish machine the bore. The sprocket will rest on that instead of relying on the bolts. This will keep it centered and transfer the weight directly to the spindle of the motor.

Then drilled the 5 bolt pattern

Now I have to mount the rotary table and machine a 1/8" recess to clear the hub flange. Need to do this because of stack up issues. Hard to explain. Remember, I got these hubs from the old transmission. So I had to work with what I got. And I also need to cut a chamfer to clear the weld between the hub and the hub flange.

Here is a close up of the cut.

That's from a plasma cutter.

If you have done all of this, without any prior machine shop experience, my hat is truly off to you. You are using tooling and setups that only someone with machine shop experience would know how to do. If you are learning this as you go it makes this thread pretty awesome.

David Devuono

Platinum Member

- Joined

- Nov 11, 2008

- Messages

- 847

- Location

- Brampton, On\lot Powassan, ON Canada

- Tractor

- Kubota B4200\MF 135\Kubota B3200

Great project, but hopefully its big enough to fit you to cause you will want to use it unless you have a real dozer. The amount of time and money I have into my second incarnation of a set of tracks, I could have purchased premade tracks and sprockets. Oh well one track is finally done and if it passes the test phase I will be investing another 100 hours into a second track.

Attachments

OP

dozerbuilder01

Bronze Member

- Joined

- Jan 13, 2012

- Messages

- 66

I watch youtube, read a lot of forums like this, read a lot of books and try. Trust me. I screw up a lot. I just don't show it hereIf you have done all of this, without any prior machine shop experience, my hat is truly off to you. You are using tooling and setups that only someone with machine shop experience would know how to do. If you are learning this as you go it makes this thread pretty awesome.

It's barely big enough to fit me. I knew that from the start. And I don't really need a dozer for myself. I don't have any property unfortunately. I live in suburbia. My neighbors are going to think I'm nuts when they see this thing. We'll take it to my brother's place so my son can play around (he has more property). I'm really just having fun building it.Great project, but hopefully its big enough to fit you to cause you will want to use it unless you have a real dozer. The amount of time and money I have into my second incarnation of a set of tracks, I could have purchased premade tracks and sprockets. Oh well one track is finally done and if it passes the test phase I will be investing another 100 hours into a second track.

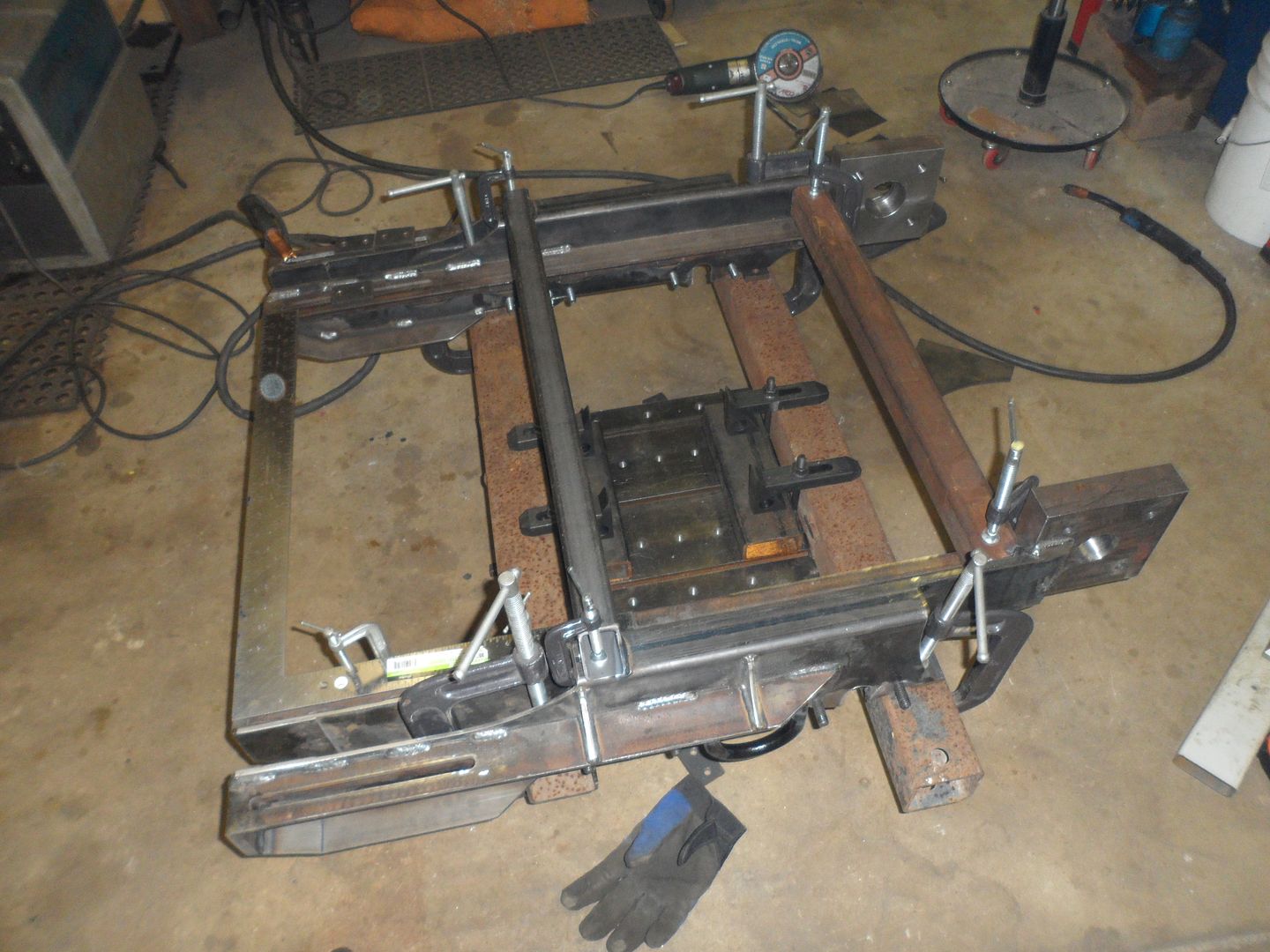

Don't have many pictures. I haven't had much time so when I'm in the garage, I've been working instead of taking pictures.

All the cross tubes and plate gussets are cut. I have a friend coming over next weekend to help me tie everything together.

CliffordK

Veteran Member

- Joined

- Mar 8, 2013

- Messages

- 2,438

- Location

- Eugene, Oregon

- Tractor

- Toro D200, Ford 1715, International 884,

What an extraordinary project.

I've seen homebuilt photos with steel tracks, but I also like the rubber tracks, and they will be easier around the garage and yard.

I like the idea of dual hydro transmissions for steering, rather than using steering brakes/clutches. Ahh, that was part of the zero-turn lawnmower. Good idea.

You need to think of some implements like a front or rear lawnmower deck. Did you keep the mower deck from your zero-turn mower?

And, of course, for a kid, a dozer blade, and maybe a front loader!!!!!

Have you seen the Orchard Cat models?

Hopefully you've been having your son help build his dozer. Where are the photos of a 5 yr old sporting a welding helmet?

I've seen homebuilt photos with steel tracks, but I also like the rubber tracks, and they will be easier around the garage and yard.

I like the idea of dual hydro transmissions for steering, rather than using steering brakes/clutches. Ahh, that was part of the zero-turn lawnmower. Good idea.

You need to think of some implements like a front or rear lawnmower deck. Did you keep the mower deck from your zero-turn mower?

And, of course, for a kid, a dozer blade, and maybe a front loader!!!!!

Have you seen the Orchard Cat models?

Hopefully you've been having your son help build his dozer. Where are the photos of a 5 yr old sporting a welding helmet?

OP

dozerbuilder01

Bronze Member

- Joined

- Jan 13, 2012

- Messages

- 66

What an extraordinary project.

I've seen homebuilt photos with steel tracks, but I also like the rubber tracks, and they will be easier around the garage and yard.

I like the idea of dual hydro transmissions for steering, rather than using steering brakes/clutches. Ahh, that was part of the zero-turn lawnmower. Good idea.

You need to think of some implements like a front or rear lawnmower deck. Did you keep the mower deck from your zero-turn mower?

And, of course, for a kid, a dozer blade, and maybe a front loader!!!!!

Have you seen the Orchard Cat models?

Hopefully you've been having your son help build his dozer. Where are the photos of a 5 yr old sporting a welding helmet?

No mower deck. I only live on a 1/4 acre in suburbia. The plow is a must though for the snow.

And my son is still a little too young to help. He'll be two in June. He'll be wanting to help before I know it though.

This has to be one of the best threads. Great Job! Just a thought for the future, can you make it remote control?

Thanks. Not full remote control but I will have a remote kill switch. It probably wouldn't be too hard to make it full remote control.

So I had a friend of mine come over last night to help out. I didn't take a lot of pictures because most of the time was spent squaring things up and getting everything held together. It was quite a challenge. I ended up within a 32nd and about 0.3 degrees across different areas. Good enough. I'm not building a spaceship.

That is all for now.

mjncad

Super Member

So I had a friend of mine come over last night to help out. I didn't take a lot of pictures because most of the time was spent squaring things up and getting everything held together. It was quite a challenge. I ended up within a 32nd and about 0.3 degrees across different areas. Good enough. I'm not building a spaceship.

That is all for now.

That's dam good and then some in my opinion.

ericher69

Veteran Member

Hurry up! Can't wait to see this thing finished.

Kidding looks awesome.

Are you going for a six way front blade?

Kidding looks awesome.

Are you going for a six way front blade?

I just finished reading the whole topic... This is a great project and I know exactly how much time, work and effort (nerves too  ) it takes to build something like this

) it takes to build something like this

Dozerbuilder, :thumbsup: :thumbsup: :thumbsup:

Dozerbuilder, :thumbsup: :thumbsup: :thumbsup:

Kyle_in_Tex

Super Star Member

Really neat, I like your craftsmanship.

OP

dozerbuilder01

Bronze Member

- Joined

- Jan 13, 2012

- Messages

- 66

That's dam good and then some in my opinion.

That little table gave me a decent base to start with. We spent a good amount of time checking checking and more checking.

Hurry up! Can't wait to see this thing finished.

Kidding looks awesome.

Are you going for a six way front blade?

I still haven't decided exactly. I think I'm going to do hydraulic up and down with manual swivel. Just a pin up front, pull it and rotate the blade. Maybe 5 total stops. But now I'm thinking, what the ****, lets do hydraulic pivot. I don't know though. I keep telling myself this is just for my son. It's just supposed to be a toy even though it's way past that.

Thanks guys for looking. I couldn't help but get the sheet metal out of the shed and put it on. It's pretty much down to the details now. The whole shape is there. I need to make sure everything fits before I weld home the underframe. After that, I hope to take it for a test spin by early summer.

npalen

Elite Member

That is frickin awesome! Nice work!!

Edit: Probably should discuss how the rubber tracks compare to R1, R2, etc.

Edit: Probably should discuss how the rubber tracks compare to R1, R2, etc.