ultrarunner

Epic Contributor

- Joined

- Apr 6, 2004

- Messages

- 29,479

- Tractor

- Cat D3, Deere 110 TLB, Kubota BX23 and L3800 and RTV900 with restored 1948 Deere M, 1949 Farmall Cub, 1953 Ford Jubliee and 1957 Ford 740 Row Crop, Craftsman Mower, Deere 350C Dozer 50 assorted vehicles from 1905 to 2006

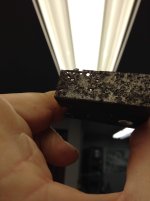

I discovered a pinhole leak in a rubber fuel line giving me problems... it would idle ok... at speed it would stop due to lack of fuel.