Sorry for the late reply, but I just remembered this thread, and the forum didn't send me updates after my last visit for some reason.

I'm not in a position to take any pictures right now (dark, cold, snowing), but I'll try to create a diagram showing what I did. First, however, a brief primer in hydraulics, which you apparently need (as I did when I got this cart and had to work out how to hook it up).

The simplest possible hydraulic system is a loop that starts and ends at a reservoir, to which a pump is attached. The pump drives the fluid from the reservoir through the loop and back to the reservoir. To make the system do work, you need to put a valve in the loop. The valve directs the fluid flow outside the loop through some kind of device, such as a cylinder or a motor. This requires an inlet from the loop, and outlet back to the loop, and a pair of work ports to which the device is attached. If the valve is closed, there's no flow in the loop. If the valve is open, the fluid flows into the valve, through the device, and back out the valve. If the valve is bi-directional, the work ports alternate between inlet and outlet for the device, depending on the valve position.

The

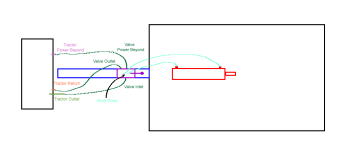

BX25 is not the simplest possible device. It has to power a lot of devices with the hydraulic system, so every valve in the loop has three ports aside from work ports - one inlet from the hydraulic loop, one outlet back to the reservoir, and one power beyond port to the rest of the loop. When the valve is closed, instead of there being no flow, the flow passes straight through on to the next valve in the loop. When the valve is fully open, flow goes through the valve's connected device and back to the reservoir. Valves further on get no power. There are priority valves in the system that guarantee flow to things like PTO and steering, though, so in practice it really means you can't use the loader, backhoe, and lift arms all at once.

The lift control lever you want to use is a valve already in the system, which has work ports that push the rear and mid-mount lift arms up and down. In order to use that valve to control the cart, you'd have to split the work ports so that flow went to the cart's cylinder as well as the lift arms. Possible in principle, but I certainly wouldn't want to try doing that.

The ports at the back of the tractor are just ways to plug additional valves into the loop, such as those on the backhoe attachment. The short hose is the outlet, which goes to the inlet of the new valve. The connector next to that is the reservoir return, which goes to the outlet of the new valve. The connector on the right, which should be occupied by the short hose when the backhoe isn't attached, is power beyond. I don't recall what order things are connected in, but I believe neglecting to attach that hose means no loader and no lift lever.

So if you don't want to run hoses to the front to use the loader valve (perhaps because you want the loader to be on the tractor when using the cart, which I certainly need), you need to buy a new valve to drive the cart's cylinder.

Assuming you have a double-acting cylinder (i.e. it requires hydraulic pressure to retract instead of letting gravity do the work), you need a bi-directional valve rated to 1800psi and 6 gallons per minute, with power beyond (which might be an optional add-on that replaces a plug with a connector).

The one I used is a Prince RD5100 (specifically, RD516CA5A4B1, which I'll explain momentarily), which cost about $140 with the power beyond adapter, and is complete overkill. The Prince RD4100 will work just fine, though the only one for sale I can find online right now is actually more expensive. The specific model you'd want is RD412BA5A1A1, which encodes all the relevant valve options (port sizes, spool type, action, relief valve, etc.). Or something equivalent, of course, which you might be able to get a local shop to help with.

Beyond that, you need hydraulic hoses and fittings. Three with quick connects to connect the valve to the tractor, and two permanent ones to connect the valve to the cylinder. I made my own with bulk hose and field-replaceable fittings, which is probably a fair bit more expensive than having them made to spec by a local shop with a crimping machine. Which fittings you need depends on what valve you get and what cylinder you have. The quick connects for the tractor are standard 1/4" parts, though which fittings you get on the hoses will determine exactly what quick connect units you need.

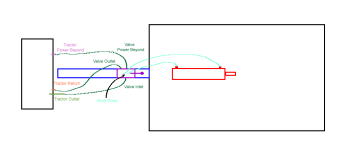

Finally, I've attached an exceptionally crude diagram showing how it's all connected.

Swapping work ports changes which way the cylinder moves for a given valve direction.

Hopefully that gives you enough information to be getting on with.