Olympus

Platinum Member

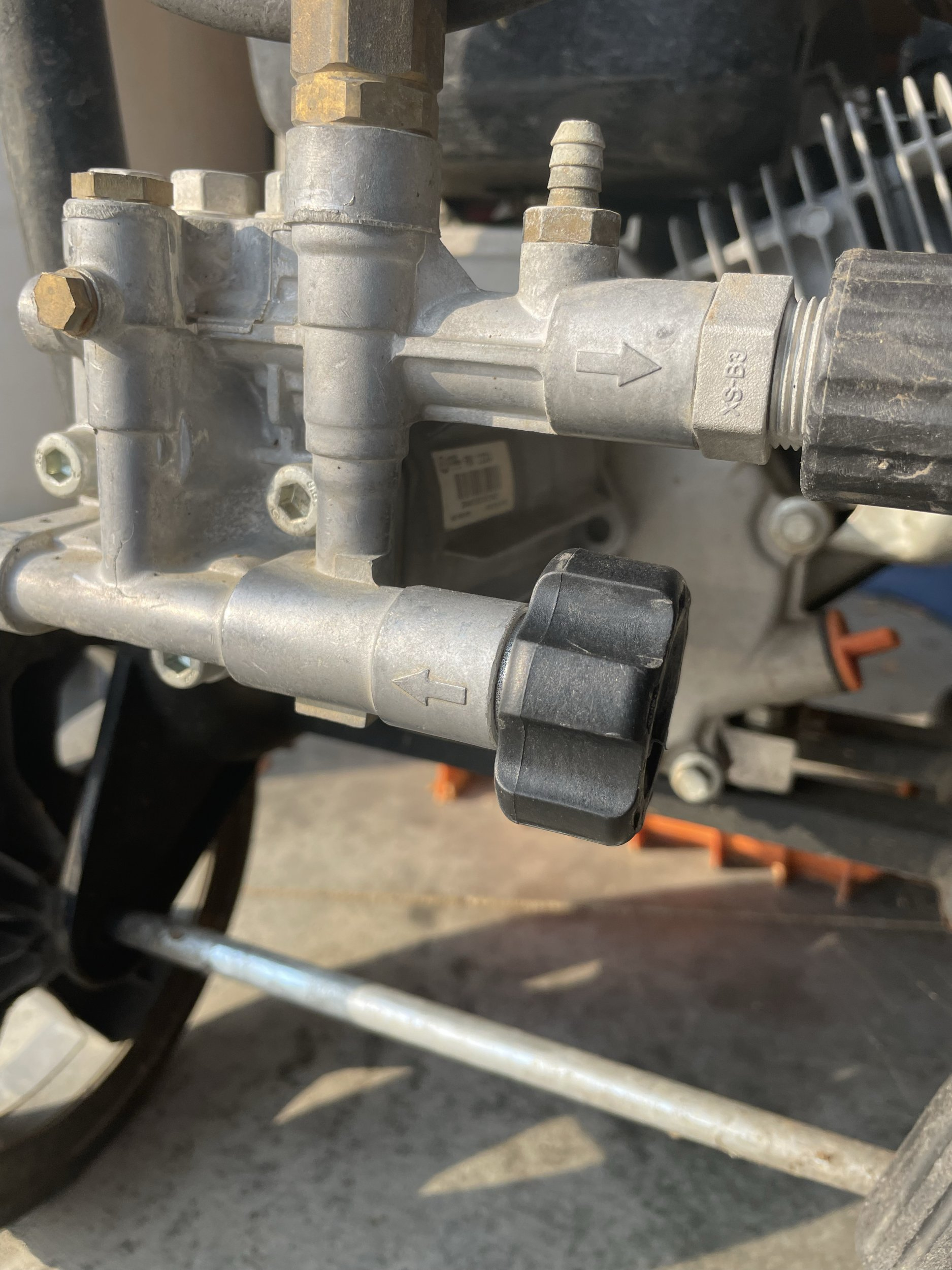

I have a Generac gas power washer and I am having problems with my water inlet fitting. It’s plastic and the threads are stripped which causes a huge fountain-like leak. For the life of me, I can’t figure out how to get the plastic female fitting off to replace it. Has anyone ever done this before?