Tinhack

Elite Member

- Joined

- Jul 3, 2020

- Messages

- 3,560

- Location

- Lytle, TX

- Tractor

- Ford 3910, John Deere 420C, Kubota G32XKS, IH 2606, Bad Boy Maverick-60"

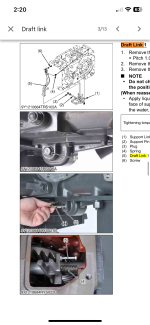

That's why you only read 30-40psi. The P port is the pressure Input to the valve. Teeing on that port will only have "Return" pressure until the valve is activated to send pressure to something through one of the Output ports. That something must Also be locked, blocked or at full extension to test pressure.Could it be possible that I have the centre valve that puts fluid into the ports located incorrectly ? . My pressure gauge is off the “p” port .

You have to "dead-head" a port to test pressure.

Last edited: