Cdash

Silver Member

I have a project in my head, and have put it on computer to see what all of you think.

What I wanted was a tooth bar, but more of an implement rather than an attachment for my bucket. Also, I can get the steel for free to do this, where a toothbar would be $$$, so that kind of drove the design as well.

This concept is built around steel I have or can get free. What I am thinking, is a FEL attachment that is a dedicated toothbar. Main thought for it is to use it as a scarifier for road maintenance and for clearing brush by running the "teeth" about 3-4" in ground and catching roots. Since it's not connected to my bucket, no worries of bending my bucket up.

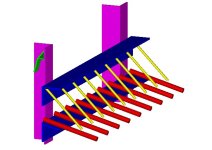

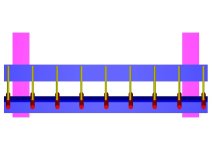

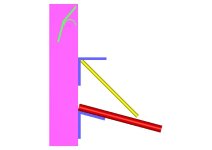

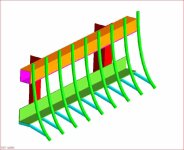

Here is one of 3 pictures (see attachment)

The purple is angle iron uprights to attach to my JD4100 loader arms with green quick-tach brackets. The blue is steel I have laying around. The bottom one is not 90 degrees (you'll see in the side view), the top one is. Both are like angle iron, but are actually 3/8" plates welded together. The red is 1" diameter re-rod (reinforcing steel) (thinking about 12" long) and the yellow is 1/2" diameter re-rod bracing the 1" teeth.

When attached to the loader the range of motion will be from the uprights being vertical (as shown in this picture) to the uprights being completely horizontal, and everywhere in-between.

The only cost will be supplies (cutting wheels, welding wire and torch gas) so before you tell me to buy a tooth bar, I am doing this because $$. But, if enough of you tell me that I am crazy, I will save my $$ for a tooth bar. Building is more fun though, and nothing beats that satisified feeling you get after a few hours of work and having somthing usefull when your done and it's fun to "invent" stuff.

I know there will be downsides since it's not part of a bucket, like digging, but for clearing roots, scraping the road (in combination with a back blade) and general raking, I think it should fit my needs well.

Open up and let me know what you think. I am looking to get opinions to see the downsides that I have not considered yet. Of course, compliments and refinements are welcome also.

Thanks for your help! (this place is great, but gets me in trouble for giving me more ideas!!)

What I wanted was a tooth bar, but more of an implement rather than an attachment for my bucket. Also, I can get the steel for free to do this, where a toothbar would be $$$, so that kind of drove the design as well.

This concept is built around steel I have or can get free. What I am thinking, is a FEL attachment that is a dedicated toothbar. Main thought for it is to use it as a scarifier for road maintenance and for clearing brush by running the "teeth" about 3-4" in ground and catching roots. Since it's not connected to my bucket, no worries of bending my bucket up.

Here is one of 3 pictures (see attachment)

The purple is angle iron uprights to attach to my JD4100 loader arms with green quick-tach brackets. The blue is steel I have laying around. The bottom one is not 90 degrees (you'll see in the side view), the top one is. Both are like angle iron, but are actually 3/8" plates welded together. The red is 1" diameter re-rod (reinforcing steel) (thinking about 12" long) and the yellow is 1/2" diameter re-rod bracing the 1" teeth.

When attached to the loader the range of motion will be from the uprights being vertical (as shown in this picture) to the uprights being completely horizontal, and everywhere in-between.

The only cost will be supplies (cutting wheels, welding wire and torch gas) so before you tell me to buy a tooth bar, I am doing this because $$. But, if enough of you tell me that I am crazy, I will save my $$ for a tooth bar. Building is more fun though, and nothing beats that satisified feeling you get after a few hours of work and having somthing usefull when your done and it's fun to "invent" stuff.

I know there will be downsides since it's not part of a bucket, like digging, but for clearing roots, scraping the road (in combination with a back blade) and general raking, I think it should fit my needs well.

Open up and let me know what you think. I am looking to get opinions to see the downsides that I have not considered yet. Of course, compliments and refinements are welcome also.

Thanks for your help! (this place is great, but gets me in trouble for giving me more ideas!!)