markpaul2929

New member

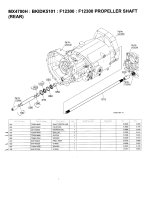

Hey guys I had oil leaking severely from the split pin plug. Called the dealers and he said its most likely the 4wd seal and the tractor needed to be split. They wanted too much so i decided to do it myself. It was my first split. It was pretty straightforward had to disconnect few hydraulic lines and electrical connections. kept the steering, dashboard panel and all the main wiring and hydraulics connected and just onbolted the main dashboard bolts and pulled it off with the engine. all in all a couple of hours. Now the issue is how do i remove that 4wd seal?

Also is the main transmission seal (inside the aluminum housing) leaking and what is the process with it for replacing it? Reall only found oil on 4wd shaft

see attached photos

Also is the main transmission seal (inside the aluminum housing) leaking and what is the process with it for replacing it? Reall only found oil on 4wd shaft

see attached photos