J_J

Super Star Member

- Joined

- Sep 6, 2003

- Messages

- 18,973

- Location

- JACKSONVILLE, FL

- Tractor

- Power-Trac 1445, KUBOTA B-9200HST

I wrote this for the PT machines, but it applies to any machine that uses loaders or BH.

Here is the main reason that the lift cyl will drift down even if the lift cyls are good.

Excerpt:

Most hydraulic valves are a metal-to-metal fit spool design, so do not depend on the cylinder setting dead still with a tandem center spool. If there are outside forces on the cylinder, it will creep when the valve centers.

Any metal-to-metal fit spool valve never fully blocks flow. With external forces working on the cylinder, it may slowly creep with the valve centered.

Well, you have the outside forces with the weight of the lift arms. Then add leaky cyl and down it drops before your eyes.

What does the metal to metal contact tell you about the leakage. Spool tolerance to bore tolerance.

It speaks to the quality of the hyd components a manufacturer wants in their machines.

They can brag about tight tolerance, but do you think the would brag about loose tolerance.

However, some of you say PT brags about how they really wanted valves that leak more than other valve competitors.

Their reasoning, is not valid.

They could say, they were purchased on price alone, and that might be true.

Need I say more, you have the facts.

My loader arms leak down over night, but if I need better, I have some needle valves that can be used.

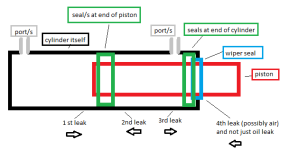

If it leaks down after that, it has to be the cyl seals.

Here is the main reason that the lift cyl will drift down even if the lift cyls are good.

Excerpt:

Most hydraulic valves are a metal-to-metal fit spool design, so do not depend on the cylinder setting dead still with a tandem center spool. If there are outside forces on the cylinder, it will creep when the valve centers.

Any metal-to-metal fit spool valve never fully blocks flow. With external forces working on the cylinder, it may slowly creep with the valve centered.

Well, you have the outside forces with the weight of the lift arms. Then add leaky cyl and down it drops before your eyes.

What does the metal to metal contact tell you about the leakage. Spool tolerance to bore tolerance.

It speaks to the quality of the hyd components a manufacturer wants in their machines.

They can brag about tight tolerance, but do you think the would brag about loose tolerance.

However, some of you say PT brags about how they really wanted valves that leak more than other valve competitors.

Their reasoning, is not valid.

They could say, they were purchased on price alone, and that might be true.

Need I say more, you have the facts.

My loader arms leak down over night, but if I need better, I have some needle valves that can be used.

If it leaks down after that, it has to be the cyl seals.