akpilot

Silver Member

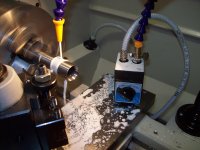

Looks like there are a few people with lathes here on the forum, so I thought I would post a inexpensive coolant system that I built for mine.

Mine came with a chip pan so that made that part easy, I drilled a hole in the chip pan then recessed the area around it better drainage, installed a fitting and hose into a bucket. In the bucket there is a second jug that the drain line goes into that has holes 6-8" above the bottom this acts as a settling pond for any chip that make it past the screen on top of the chip pan.

I used a cheap submersible decorative pond type pump (Lowes) that pumps the clean fluid back up to a magnetic based coolant hose, which can be set on the carriage to travel with the cutting tool.

The one pic shows the switch that I installed, it's a three position switch, ON (when chuck is turning) - OFF - ON (all the time) It's nice when the chuck is turned off for a measurement the fluid stops, when the chuck is turned back on the fluid starts again. I got the wiring info from Steve Bedair (see his website) of course the wiring diagram wouldn't be the same, unless you have one like ours.

I used Primrose cutting fluid, which is mixed 15 to 1 with water. H8257 is Grizzly's part number.

Overall it's easy to do and works great!!

Mine came with a chip pan so that made that part easy, I drilled a hole in the chip pan then recessed the area around it better drainage, installed a fitting and hose into a bucket. In the bucket there is a second jug that the drain line goes into that has holes 6-8" above the bottom this acts as a settling pond for any chip that make it past the screen on top of the chip pan.

I used a cheap submersible decorative pond type pump (Lowes) that pumps the clean fluid back up to a magnetic based coolant hose, which can be set on the carriage to travel with the cutting tool.

The one pic shows the switch that I installed, it's a three position switch, ON (when chuck is turning) - OFF - ON (all the time) It's nice when the chuck is turned off for a measurement the fluid stops, when the chuck is turned back on the fluid starts again. I got the wiring info from Steve Bedair (see his website) of course the wiring diagram wouldn't be the same, unless you have one like ours.

I used Primrose cutting fluid, which is mixed 15 to 1 with water. H8257 is Grizzly's part number.

Overall it's easy to do and works great!!