Kubota3710

Bronze Member

Good grief. What a great idea I should have thought of. Thanks for the help.

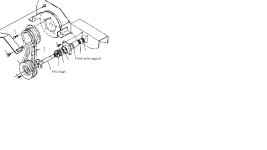

I haven't been able to get the zerk on a G1800 front PTO shaft to take grease. Finally backed it out a few turns and it took grease. I think the threads are too long and it is up against the shaft so no grease can go in. I found this with suggest different thread lenghts for grease fittings. Going to grind down the current one or find one with shorter threads. Just componds the problem with getting one. The G1800 parts diagram doesn't even show a grease fitting, so I guess Kubota just replaces it with one off their shelf.

METRIC GREASE FITTINGS | METRIC ZERK FITTINGS | METRIC GREASE FITTINGS

Second that, completely. Hard to imagine one zerk can wreak so much damage when not doing it's job, but no grease on a close tolerance spinning shaft's a disaster waiting to happen.That was a good read, a nice fix it story, excellent pics. Probably got it fixed none to soon for the grass mowing season.