You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Backhoe JW-03 Backhoe Problems

- Thread starter cv63usafsfs

- Start date

- Views: 37834

More options

Who Replied?

/ JW-03 Backhoe Problems

#41

Certainly should check fluid level, but don't believe I'm low.

I did run across this Parts Manual yesterday:

http://www.pegasus-industries.com/manuals/BackhoeParts.pdf

I did run across this Parts Manual yesterday:

http://www.pegasus-industries.com/manuals/BackhoeParts.pdf

little_fellow

New member

Hi everyone. I was looking for info on the JW03 backhoe and I stumbled onto this post. I am wondering how to check the pressure on the relief valve. I don't see a port where a gauge can be hooked up. Is this done by teeing into something.

This is a project I am working on. I took the Valve bank off the JW03 backhoe and took it all apart. I did find a few issues with it and now I am ready to reinstall it. Even though I did not play with the settings on the relief valve, I suspect it's been tampered with so I wonder how is the pressure checked on the relief valve and also, how much pressure should I have there?

This is a project I am working on. I took the Valve bank off the JW03 backhoe and took it all apart. I did find a few issues with it and now I am ready to reinstall it. Even though I did not play with the settings on the relief valve, I suspect it's been tampered with so I wonder how is the pressure checked on the relief valve and also, how much pressure should I have there?

This is a project I am working on. I took the Valve bank off the JW03 backhoe and took it all apart. I did find a few issues with it and now I am ready to reinstall it. Even though I did not play with the settings on the relief valve, I suspect it's been tampered with so I wonder how is the pressure checked on the relief valve and also, how much pressure should I have there?

This is a project I am working on. I took the Valve bank off the JW03 backhoe and took it all apart. I did find a few issues with it and now I am ready to reinstall it. Even though I did not play with the settings on the relief valve, I suspect it's been tampered with so I wonder how is the pressure checked on the relief valve and also, how much pressure should I have there?Attachments

RonMar

Elite Member

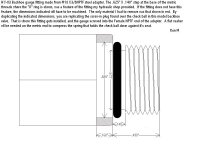

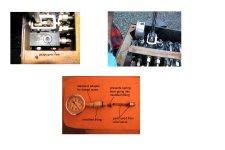

I machined a pressure gauge adapter that screwed into the check valve access plug on the top left of the valve body(has a large screwdriver slot on top) that allowed me to install a gauge there. I used an off the shelf 18MM to national pipe thread adapter and cut the shoulder back a little on a lathe to allow it to reach down into the hole far enough. I made a few for those who requested them and I believe I posted the dimensions in a thread here. Search this Chinese forum for "JW-03". I took a quick look and didn't find it... basically I machined the middle of the metric to NPT adapter to match the screw in plug contour with a shelf for the Oring, screwed it in where the plug was and screwed a gauge into that. Worked great...

RonMar

Elite Member

Ron Jindra was nice enough to send me these to repost as I lost track of them somewhere.

Here are the specs for making a gauge adapter and shows how/where it gets installed on the JW-03 control valve.

Good luck.

Here are the specs for making a gauge adapter and shows how/where it gets installed on the JW-03 control valve.

Good luck.

Attachments

little_fellow

New member

Thanks Ron. This information will be very useful. Would you happen to remember how many PSI would be preferable for this unit. I will be pressurizing it from a 7.2 GPM 540 RPM PTO Pump.

little_fellow

New member

I think that I found my answer in the PTO pump instruction manuel. It says here to set the relief valve at or below the rated pressure of 2,250 PSI.

erj

Gold Member

I have always been nervous about too much pressure, so I always set mine at 2,000psi and over the years it has been adequate.

RonMar

Elite Member

2250 Should be fine. In the dim recesses of my brain I seem to recall the Chinese manuals spec(in Bar) is actually a little higher than that, but you need to protect for the lowest rated component in the system. Often that component is the pump... Hydraulically the only real issue I had with mine was the return line into the tank. This is a low pressure line. They used a high pressure line thru a banjo fitting with about a 10MM bore. This sends the fluid back into the tank at high velocity. What mine was doing was this straight stream was shooting back across and into the top of the fluid level and pulling air down into the fluid right in front of the pump suction line. Shoot a straight stream from a garden hose nozzle into a bucket of water and you will see what I am talking about. Hydraulic pumps don't like air in the oil and will complain by making excessive noise(wine/squeal). I replaced the return line with a large diameter hose and a large bore hose barb into the tank when I installed a filter and the pump immediately went quiet...

At any rate 2250 is plenty enough force to break parts of the structure. You have a welder right? Pay close attention to the top of the bucket opening. I may have gotten a Friday bucket, but they put a piece of angle iron across the top of the opening for re-enforcement. Mine was basically held in place by about 3" of weld total across the entire width of the bucket and ends. It was a hard spot to weld and hard to inspect. This led to deformation and separation of the bucket sides from the back/top at the top corners. The top of the bucket opening is probably one of the highest stress areas on the BH when you curl and rip. All the stress from the teeth get transferred up the sides of the bucket to the corners of the opening then inward to the pivot. If the top/corner support(that crossbar) isn't adequate or welded properly to hold things square, the bucket will fail. Once damaged it was quite a bit of work to reshape and put in a proper piece of steel(3/8 X 2 X opening width) strap properly welded... If you can weld and fab, I would recommend this modification before you really use it hard as cutting out what is there and welding in the new stronger strap would be real easy and take about an hour on an un-damaged bucket...

At any rate 2250 is plenty enough force to break parts of the structure. You have a welder right? Pay close attention to the top of the bucket opening. I may have gotten a Friday bucket, but they put a piece of angle iron across the top of the opening for re-enforcement. Mine was basically held in place by about 3" of weld total across the entire width of the bucket and ends. It was a hard spot to weld and hard to inspect. This led to deformation and separation of the bucket sides from the back/top at the top corners. The top of the bucket opening is probably one of the highest stress areas on the BH when you curl and rip. All the stress from the teeth get transferred up the sides of the bucket to the corners of the opening then inward to the pivot. If the top/corner support(that crossbar) isn't adequate or welded properly to hold things square, the bucket will fail. Once damaged it was quite a bit of work to reshape and put in a proper piece of steel(3/8 X 2 X opening width) strap properly welded... If you can weld and fab, I would recommend this modification before you really use it hard as cutting out what is there and welding in the new stronger strap would be real easy and take about an hour on an un-damaged bucket...

little_fellow

New member

Thanks Ron. This is valuable info and I will definitely investigate this further.

little_fellow

New member

So Ron. About the return line. Would I be using the original fitting on the valve body and from there increase the size to I'm thinking one inch into a filter?

RonMar

Elite Member

Yes, I used the original line to a hose barb on the filter inlet port. I think I used 5/8 heater hose from filter to tank. When I installed the filter in the factory line, the backpressure caused by the banjo at the tank fitting would cause the rubber seal at the spin on cartridge to blow out when the fluid got warm. I think I welded on a 1/2 NPT street elbow over that banjo port(large end onto the tank) and a piece of 5/8 heater line slipped right on to the small end of the street el and could be clamped in place... This got rid of the backpressure issue in the filter been working that way ever since.

little_fellow

New member

OK. Thanks Ron. I should be OK then. The tank I had to buy for this unit has a 3/4 in. NPT. return port. I will attempt to install a 1 in. hose from the valve bank to the filter into the return port.

little_fellow

New member

I am having trouble now after finally putting this JW03 In operation, I find the swing from side to side way too fast, the main boom up and down seem normal. The bucket curl in and out seem to be normal and the stick boom seems to be using allot of horse power to go up and down. The return line seems to be building up pressure ( not 100% sure about this but I have a one inch rad hose there for return line with 2 hose clamps on the one end and oil is seeping out at that point). What I did for a return to the tank is that I welded a 90 degree Pipe thread fitting to the original banjo fitting from the return port. From there I screwed on a 1 in. barb fitting, attached the one inch hose to it and into a 10 micron filter before entering into the reservoir. Any suggestions?

Bob Rooks

Elite Member

Is the reservoir properly vented?

Does your return filter head have a relief/by-pass valve?

Is the flow through the filter in the correct direction?

And you would normally use the low pressure "rad hose" between the return filter and the reservoir.

You can correct the radical swing movements with copper or soft aluminum restrictor washers in the hose connections. This is sort of a trial-and-error method, but start out with a 3/16" orifice.

It's possible that you have some debris in the valve stack causing excessive power demands for boom operation. The jib seems ok though?

Does your return filter head have a relief/by-pass valve?

Is the flow through the filter in the correct direction?

And you would normally use the low pressure "rad hose" between the return filter and the reservoir.

You can correct the radical swing movements with copper or soft aluminum restrictor washers in the hose connections. This is sort of a trial-and-error method, but start out with a 3/16" orifice.

It's possible that you have some debris in the valve stack causing excessive power demands for boom operation. The jib seems ok though?

little_fellow

New member

The fill cap serves as a vent. The return filter head has no relief/by-pass valve. The flow is in the right direction.

Bob Rooks

Elite Member

I'm then assuming that you have a spin-on return filter element, the by-pass valve should be inside it.

3/4" NPT 25 GPM Zinga Return Line Filter 25 PSI Bypass | Filters | Hydraulic Filters | Hydraulics | www.surpluscenter.com

1� Micron Replacement Element w/18 PSI Bypass | Filters | Hydraulic Filters | Hydraulics | www.surpluscenter.com

3/4" NPT 25 GPM Zinga Return Line Filter 25 PSI Bypass | Filters | Hydraulic Filters | Hydraulics | www.surpluscenter.com

1� Micron Replacement Element w/18 PSI Bypass | Filters | Hydraulic Filters | Hydraulics | www.surpluscenter.com

little_fellow

New member

Your right about the inside bypass. This is my Prince FA1300-00 Filter Head, Cast Aluminum, 25 psi Bypass Spring, 20 gpm, 3/4" NPT Female and my spin on is a 10 micron.

little_fellow

New member

Thanks

RonMar

Elite Member

A 1” line shouldn't build any pressure. How big was the hole where you welded the fitting over at the tank?

As for your operation, the valve on my 03 uses adapters on the ports to get from the port thread to the o-ring face seal fittings on the hoses. Two of my adapters had reduced size ports in two of those adapters(on the swing circuit). Found this out when I rebuilt mine. Part of my redesign rotated the valve around 180 degrees which re-assigned valve functions to different circuits. When I reconnected all the hoses, my boom swing was wildly fast and one of the other circuits was slow. A closer look found the restricted port adapters... once swapped to the appropriate location, things went back to normal...

As for your operation, the valve on my 03 uses adapters on the ports to get from the port thread to the o-ring face seal fittings on the hoses. Two of my adapters had reduced size ports in two of those adapters(on the swing circuit). Found this out when I rebuilt mine. Part of my redesign rotated the valve around 180 degrees which re-assigned valve functions to different circuits. When I reconnected all the hoses, my boom swing was wildly fast and one of the other circuits was slow. A closer look found the restricted port adapters... once swapped to the appropriate location, things went back to normal...