What's this about pipe threads ? This all my manual has about the screen ...

All the Japanese tractor manufacturers came up with different setups to access that cleanable screen type suction filter. Some didn't even include that feature - although most did.

My guess is the cleanable screen crud flter itself on modern compacts is a holdover on some from the earlier tractor designs from the 1970s&80s when that feature was common to all small 4wd imported tractors.

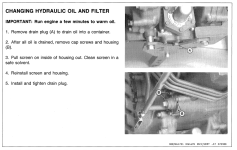

The filter covers can be located low down or underneath and on either side of the common transmission/hydraulic fluid sump. It varies. A few didn't have it at all. A triangular cover having three bolts is a pretty common way to identify the removeable filter cover - as your photos show. That weird triangular 3 bolt cover seems to be a common feature on Yanmars and also on the tractors Yanmar made for JD.

There is a non-critical cover gasket under the cover. Most folks either make one or use RTV...or both.

BTW, is the manual you are using specific to the 670? Or something more general? The photos you posted seem to be two different sites for that same cover. Some of the imports did had the cover back by the PTO or near the draw bar.

Like "qualsite" says, the screen is commonly found to be covered with crud and/or smashed. Straighten it out and reuse. The screen usually fits loosely over a couple of projections. It is not a fluid-tight fit at all. You can make your own with 200 mesh stainless steel hardware cloth from Ace hardware, or even sew on patches with stainless steel thread.

I've never seen or heard of the cover or insides screen fitting pipe threads, nor one where the cleanable screen had enough entry clearance so the filter could be changed in size. My guess is that qualsite's tractor is different from typical Yanmar/JD. Or maybe his had been modified before.

Luck,

rScotty