Hey JB79:

Ok that Screen should NOT be flat they should be round or pleated. that is there to keep large debris from getting sucked into the pump. If it is flat then the pump is starving for fluid and sucking air in past the front seal or in from one of the pump o-rings. You will need to replace that suction screen (under the seat & under the tube plate) with a new one, they can be had from several places.

The next thing to make sure of is that the Hyd Fluid is not getting into engine thru the front seal of the hyd pump. If the pump was dead headed or someone put too much pressure onto hyd.s then that seal maybe damaged. If that is the culprit then you can replace that seal or the pump. they are not too bad of price 120 +/- or so bucks from states side supplier or go FedEX and buy one from china for 80 or 90.

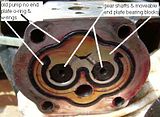

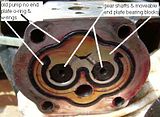

You can also buy rebuild kits for these pumps for a 20 or 30 bucks which are really just the shaft seal and two formed rubber O-Rings that fit into the pump body. just be aware the pump can not be fully tightened down as it will bind up there needs to be a fraction of inch loose/slop between the plates and pump body.

Pump has 2 bolts that holds the body and end plates together and catty-corners are two longer bolts that bolt it to the tractor engine front drive gears. I rebuilt mine but didnt get it quite right and just put on a NEW pump. My brother Pressure Washed my tractor after he used it and the high pressure water stream went between body of pump and end plate cutting the seal... He figured the pump looked greasy so he sprayed it really well :/

You can also take some grease and put a little coating around the pump body (Aluminum part) and the steel ends on it (o-rings between the two) as a test to see if that stops the air sucking.

went & got some old picks post for ya,

FYI I think there were 2 types of pumps if I remember right, see pic above.

Mark