If you lost reverse after removal of valve body, my guess is you got one of the oil lines out of place. They are very difficult to install with out splitting the tractor. The forward clutch probably needs to be resealed and possibly linings replaced. Forward clutch is accessed when split at clutch housing. Reverse clutch and oil lines are accessed at split between clutch housing and transmission case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

jd400 yellow tractor with backhoe- shuttle shift misery

- Thread starter markmc60

- Start date

- Views: 31228

-

- Tags

- john deere 400

More options

Who Replied?

/ jd400 yellow tractor with backhoe- shuttle shift misery

#11

jb1390

Gold Member

If you lost reverse after removal of valve body, my guess is you got one of the oil lines out of place. They are very difficult to install with out splitting the tractor. The forward clutch probably needs to be resealed and possibly linings replaced. Forward clutch is accessed when split at clutch housing. Reverse clutch and oil lines are accessed at split between clutch housing and transmission case.

Those lines should not generally come out when removing the valve. There is a plate behind the valve assembly, with an additional couple bolts that holds the lines in place. However, there are a few check valves and regulator springs that need to be carefully reassembled. I concur with the general theory of the forward o ring being shot, though that can be tested with compressed air fairly easily.

OP

markmc60

New member

- Joined

- Jul 27, 2011

- Messages

- 16

- Location

- Palmer Texas

- Tractor

- JD4430,Ford 600, cub, JD400 backhoe, JD450 dozer, Cat 913 motor scraper, Allis Chalmers D grader

Those lines should not generally come out when removing the valve. There is a plate behind the valve assembly, with an additional couple bolts that holds the lines in place. However, there are a few check valves and regulator springs that need to be carefully reassembled. I concur with the general theory of the forward o ring being shot, though that can be tested with compressed air fairly easily.

with compressed air?, injected where? I am a little weary of this old JD, I have worked on a many a tractor but not much good on transmixers.......... just tore my jd450 dozer down past the rear quills and back together, that was a chore. still scraping cash together to replace the tracks and rollers..........soon. then I get my backhoe in the shop and play with it

jb1390

Gold Member

with compressed air?, injected where? I am a little weary of this old JD, I have worked on a many a tractor but not much good on transmixers.......... just tore my jd450 dozer down past the rear quills and back together, that was a chore. still scraping cash together to replace the tracks and rollers..........soon. then I get my backhoe in the shop and play with it

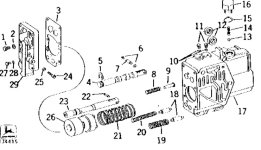

Picture 1: you see the screws labeled as "11" - those screws are test ports for the forward and reverse control circuits. You may be able to apply compressed air to those ports. I did not try that when I had my machine, and if you have leakage, that may indicate a valve problem not necessarily an internal issue.

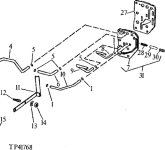

Picture 2: If you remove the reverser control valve, there are oil lines that go directly to the reverse/forward clutch cylinders. If you apply air to those, they should engage either the reverse or forward clutch pack, depending on the line you are pressurizing. I believe the lines you need to pressurize are labeled 8 and 9. This is what I did when I had this problem on my 300. After replacing the forward o-ring, it would hold pressure. It would not hold pressure on forward clutch pack originally.

Tx Jim

New Member

Ditto what jb1390 stated about checking for hyd leak with air. BTDT several times when I was a JD dealer service manager.

OP

markmc60

New member

- Joined

- Jul 27, 2011

- Messages

- 16

- Location

- Palmer Texas

- Tractor

- JD4430,Ford 600, cub, JD400 backhoe, JD450 dozer, Cat 913 motor scraper, Allis Chalmers D grader

thanks for all the help, when I get my backhoe in the shop I will let yall know where we are, I have a couple of projects in front of it, my 450 dozer and a 401 ag tractor that wont start and needs the water pump rebuilt............. just typical.

Jet A

New member

Any update on the JD 400 reverser issue?

OP

markmc60

New member

- Joined

- Jul 27, 2011

- Messages

- 16

- Location

- Palmer Texas

- Tractor

- JD4430,Ford 600, cub, JD400 backhoe, JD450 dozer, Cat 913 motor scraper, Allis Chalmers D grader

Any update on the JD 400 reverser issue?

sorry, not yet, I have not moved the backhoe into the shop yet............. just swamped, trying to get my 613 scraper going and my allis chalmers D12 engine rebuilt.

TonyDeb

New member

- Joined

- Jan 17, 2017

- Messages

- 8

- Location

- Watertown, CT

- Tractor

- JD 400 Industrial, Massey Fergason 40 Industrial, Ford 8N

I am having the same issue as Mark. My '72 JD 400 works in reverse not forward. Test pressure is 145 as it should be at rev test port but only 25 at forward test port. I bought used rev control valve $150 (cheaper then the rebuild parts) but has same issue. I assume there is a leak in the forward circuit after the valve. I must split tractor. How do I know if I need to rebuild the forward clutch pack or can I assume it's just the oil line O ring that goes to forward clutch? Also, should I split it at the differential side of housing or the engine side? Thanks!

jb1390

Gold Member

I am having the same issue as Mark. My '72 JD 400 works in reverse not forward. Test pressure is 145 as it should be at rev test port but only 25 at forward test port. I bought used rev control valve $150 (cheaper then the rebuild parts) but has same issue. I assume there is a leak in the forward circuit after the valve. I must split tractor. How do I know if I need to rebuild the forward clutch pack or can I assume it's just the oil line O ring that goes to forward clutch? Also, should I split it at the differential side of housing or the engine side? Thanks!

If I recall correctly, I think you need to split at both sections. Your choice on which one first. The center section that is removed contains the clutch packs. I would test with air as discussed above before splitting, but chances are your forward O-ring is shot. Your decision on what parts need to be replaced will come after internal inspection. If the clutches are in ok shape, you may be able to get away with just seals. I did everything when I split mine for peace of mind.

Get a manual for the machine if you do not already have one. The manual for this machine is pretty detailed.