You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Iseki G192 TS1910 19

- Thread starter ebattin

- Start date

- Views: 30244

More options

Who Replied?

/ Iseki G192 TS1910 19

#21

DanCin

New member

- Joined

- Aug 24, 2014

- Messages

- 12

- Location

- Cartersville, GA.

- Tractor

- 1980 BOLENS G-194, ISEKI TS 1910LF

Darryl,

Thanks for the link.... that helps, I will definitely try that tomorrow or next day. It is odd that you are in Carterville, IL, and I am in Cartersville, GA.

I'll update you later this weekend,... trying really hard to get this little tractor running, but being Holiday weekend have other events scheduled.

Can you or anyone suggest a place to purchase a new manifold and an upgraded seat? My manifold is cracked in the turn upward. {can it be welded?} The seat is totally gone... Do you or anyone have the Air Filter part # for the ISEKI TS1910. I found one by WIX, very similar for the BOLENS G-174, but it is shorter than the filter for the G-194.

Any Suggestions or advise is appreciated and welcomed about the ISEKI TS1910 tractor.

Thanks,

Dan

Thanks for the link.... that helps, I will definitely try that tomorrow or next day. It is odd that you are in Carterville, IL, and I am in Cartersville, GA.

I'll update you later this weekend,... trying really hard to get this little tractor running, but being Holiday weekend have other events scheduled.

Can you or anyone suggest a place to purchase a new manifold and an upgraded seat? My manifold is cracked in the turn upward. {can it be welded?} The seat is totally gone... Do you or anyone have the Air Filter part # for the ISEKI TS1910. I found one by WIX, very similar for the BOLENS G-174, but it is shorter than the filter for the G-194.

Any Suggestions or advise is appreciated and welcomed about the ISEKI TS1910 tractor.

Thanks,

Dan

DanCin

New member

- Joined

- Aug 24, 2014

- Messages

- 12

- Location

- Cartersville, GA.

- Tractor

- 1980 BOLENS G-194, ISEKI TS 1910LF

DARRYL, YOU ARE THE MAN! Your tip was the trick. I opened each Injector tube, pressurized the fuel tank a little, spun the engine with shut off valve closed, the diesel poured thru tubes to the Injectors, tightened the tubes back down, opened the shut off valve, and it fired off immediately. Motor runs good... now just to grease and lubricate, ad clean up. I still need Air Filter number for WIX filter to fit the TS1910. Thanks for everyone's help "KEROPELLI", "63DH8", & "LENS12" for all your help and suggestions... that coached me to getting this old Tractor running again. If any one has the part number of the Air Filter, the best replacement seat, for the ISEKI TS1910 or BOLENS G-194 tractor, the info would be greatly appreciated.

Kernopelli

Veteran Member

- Joined

- Oct 16, 2006

- Messages

- 2,210

- Location

- Carterville, Illinois

- Tractor

- Mitsubishi MTE2000D, Dig It 258 Mini Ex, Deere Z930A ZTR

Glad it worked. Cartersville/Carterville.......My son pulled a horse trailer down to Macon last week and he got home and was talking about Cartersville GA. Used to drive through your area myself 1-2 times a year back in the day!

The manifold is probably cast ( hard to weld)...might try brazing it. New ones are only $55 http://bestfarmparts.com/bolens-exhaust-manifold-g192-g194-p-2120.html.

Cant give you a WIX number for the air filter but Bolens/Iseki air filters are easily found on Google.

Seat.....They always seem to sell for more than I think they should! I'd just check tractor seats on Ebay or google. Can probably find a decent Iseki replacement for $50-60 on Ebay.

The manifold is probably cast ( hard to weld)...might try brazing it. New ones are only $55 http://bestfarmparts.com/bolens-exhaust-manifold-g192-g194-p-2120.html.

Cant give you a WIX number for the air filter but Bolens/Iseki air filters are easily found on Google.

Seat.....They always seem to sell for more than I think they should! I'd just check tractor seats on Ebay or google. Can probably find a decent Iseki replacement for $50-60 on Ebay.

Last edited:

terraformer

Silver Member

I have had the exhaust manifold elbow adapter break off on my 1910. I have not had the best experience welding cast iron so I had a welder fix it, he used some special rod I am pretty sure it is not brazed. Came out great. I made a brace from the front of the tin to the top of the stack to help prevent me hooking it a second time.

DanCin

New member

- Joined

- Aug 24, 2014

- Messages

- 12

- Location

- Cartersville, GA.

- Tractor

- 1980 BOLENS G-194, ISEKI TS 1910LF

Actually, on my tractor, it is the curved piece that goes up to the muffler that has cracked, it leaks exhaust gases, but not that bad, I am just going to use it, until I can replace that piece, thanks for the tip making a support brace. The muffler will have to be replaced soon... it is blowing pieces of hot metal out, because it was open to rain for several years.

terraformer

Silver Member

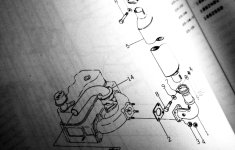

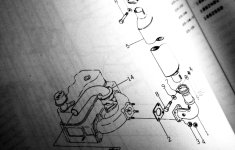

Yes mine cracked at the 90 degree curved part. The angle casting had two short bolted in braces along side the casting that prevented the muffler from falling off.

The link shows a curved head pipe, replacing the curved casting.

The curved manifold must have had a design flaw.

You should get your manifold welded. Mine was welded without removing it from the tractor.

The link shows a curved head pipe, replacing the curved casting.

The curved manifold must have had a design flaw.

You should get your manifold welded. Mine was welded without removing it from the tractor.

Attachments

Last edited:

GILBERtmendoza

New member

- Joined

- Jun 28, 2024

- Messages

- 1

- Tractor

- Ts1910

How much

Here are some similar links:

- Replies

- 4

- Views

- 479