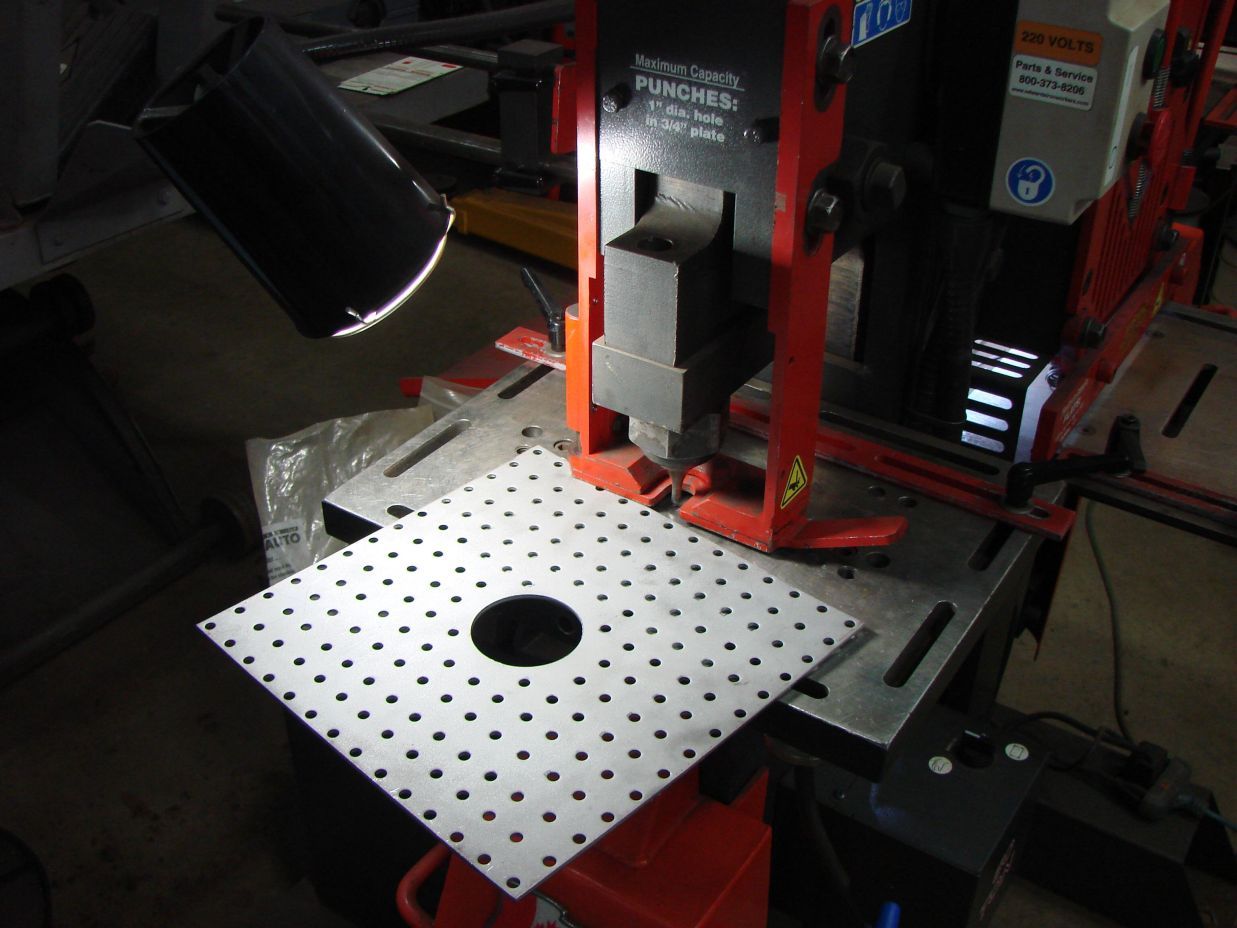

Peddinghaus are the top of the line but there's a lot of good ironworkers available. I was looking at Piranha and they look like a really well designed unit. The Uni-Hydro's are cheaper and a little bit crude looking. I remember reading that the guy that started Uni-Hydro used to be with Scotchman but they had a falling out. Scotchman are a good ironworker but guys that have used them, say they are slower than some other hyd. models. I've used a 105 ton Peddinghaus mechanical, 125 ton Kingsland Hydraulic and a couple smaller Mubea mechanical ironworkers as well as a 40 ton Uni-Hydro. The mechanical are real FAST! but can be very dangerous. Once you hit the button or pedal, there's no stopping it for an emergency. That's a big reason they don't make them anymore. I did like the mechanical better for punching holes because you could lower the punch into your center punch mark and just push a button for an instant hole. The hyd., you could do that but you had to change a hyd. function and then switch it back to punch the hole. Some hyd. let you put the punch on the plate but overall for punching holes a mechanical is faster. For other functions the hyd. shines because you can change tools for different applications. The hyd. is much safer because you usually have to keep pushing on the pedal/control until you're finished. The rule of thumb to remember when punching holes is that on mild steel, the smallest hole you can punch in a specific plate is the same diameter as the plate thickness. So if you have 1/4" plate, 1/4" is the smallest hole you could punch, 1/2" plate-1/2" hole. If you tried to punch say a 3/8" hole in 1/2" plate, you stand a good chance of breaking the punch. I think there are special punches available for doing smaller holes in thicker plate? Most punches do have a dimple to line up with a center punch mark and some punches also have a scalloped cutting edge to make punching easier. The cutting edge is on an angle to work like a shear and lower the pressure required for punching the hole.