J_J

Super Star Member

- Joined

- Sep 6, 2003

- Messages

- 18,973

- Location

- JACKSONVILLE, FL

- Tractor

- Power-Trac 1445, KUBOTA B-9200HST

Would you tell us how the valve works. and some pictures.

Thanks JJ, do we know which we use the 10 or 20 pound?

Also anyone able to post pictures of the hydraulic replacement for the Hydroback cable--as used on the new machines?

Thanks

Bill

Thanks. That is the first time I have seen that valve. Logic tells me that the pedal is operating a lever that sends fluid to the transmission to shift the pump swash plate, which will vary the speed of the wheel motors.

Hee hee!!! Because we all took pictures of them when they were new because we know what they'd look like in a few weeks of use!How come everyones tractor is so clean in the engine compartment? No matter what I do it is full of oil and debris. I think I pull and wash the junk out and it just crawls back in to tick me off...

No I do not know the manufacturer of that pump.David,

Do you know the manufacturer of that pump? I see what looks like the letter P, and I can't see the letter beside the P?

It looks so clean because it probably was pressure washed.

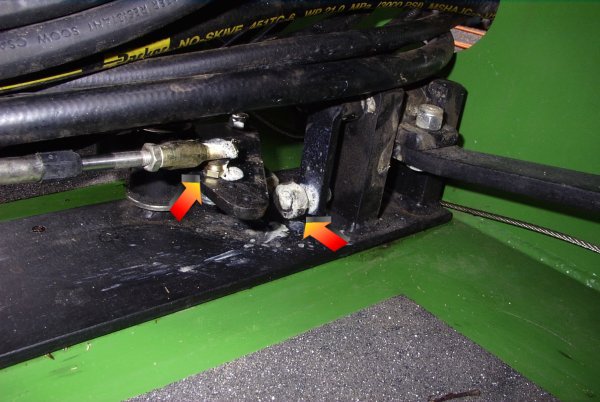

I grease the grease fittings every 10 hours, but have not been lubing the heim joints. I guess I should start. I leave the covers off. I don't see that they are needed except for appearance. Is that right.

If I leave the covers off all the grass that blows down the tunnel seems to go up my nose!I grease the grease fittings every 10 hours, but have not been lubing the heim joints. I guess I should start. I leave the covers off. I don't see that they are needed except for appearance. Is that right.