Sawyer Rob

Super Member

I don't think 1/2" hoses is big enough...

SR

SR

I don't think 1/2" hoses is big enough...

SR

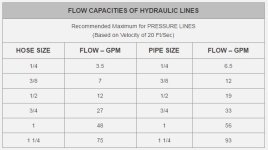

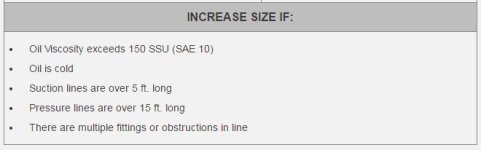

My powerpack is operating at 3000 psi? On a 45 hp tractor. But my flow is 15 gpm. In order to reach 20 psi i think they told me id need a 75 hp tractor ( as i recall).I’m kind of in the same boat, honestly. I’ve been trying to figure out the whole “brush cutter + separate hydraulic power unit” setup myself, especially when the tractor hydraulics don’t give enough flow or pressure. I ran some numbers using a hydraulic power pack calculator I’ve been using…but I still get stuck at the same question you’re asking - once you size the pump for ~21 GPM @ 2000 psi (since that’s all the PTO HP allows), what do you actually do when most cutter motors are designed around higher pressure systems (2500–3000 psi)? It seems like hitting the required blade torque at only 2000 psi forces the flow way higher than what PTO horsepower can realistically handle.