TORQUIN

Silver Member

Is there a web site or book I can get to learn how to calculate material strengths for a project?

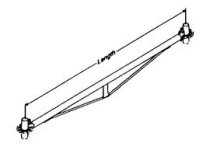

For example, I just bought a stock trailer to store my stump grinder in, for the shelter and transportation. It was much cheaper than an enclosed cargo trailer, from the prices I see around here. The trailer came with a 3' ramp that was too short for the height of the trailer, when driving a stump grinding up it. I used some angle and expanded metal from a dirt strainer project I did a few years ago to lengthen the ramp. The angle iron used is 2"x2"x1/8" cold roll and I overlapped the old ramp by 12", and extended the ramp out 45" from the original 3'. I welded it on to the old ramp in strategic locations and proceeded to try it out.

As I drove the 3000 lb stump grinder across the ramp it bowed beginning where the ramp extension overlaps the old ramp and extending along the ramp extension.

My best guess at this time is that the 2"x2"x1/8" angle on the sides is not strong enough and I need to reinforce it. I'm thinking that I could just overlay another piece of angle there, of the same dimensions, and double my thickness for that area. I'm not sure how long a piece I should use, if I should go the entire length of the ramp extension or just a 12-18", or what.

This is why I would like to learn how to calculate what I need, so I don't have to be back and redo these things. Usually I overbuild things so I don't have to worry about it, but in this case I need to keep the weight down as I'm the one that has to lift this ramp twice at every stump job.

![20131112_075020[1].jpg 20131112_075020[1].jpg](https://www.tractorbynet.com/forums/data/attachments/328/328241-074455fd1102cdad15676fb91868508d.jpg)

Not sure why the pic uploaded sideways.

Thanks,

Chris

For example, I just bought a stock trailer to store my stump grinder in, for the shelter and transportation. It was much cheaper than an enclosed cargo trailer, from the prices I see around here. The trailer came with a 3' ramp that was too short for the height of the trailer, when driving a stump grinding up it. I used some angle and expanded metal from a dirt strainer project I did a few years ago to lengthen the ramp. The angle iron used is 2"x2"x1/8" cold roll and I overlapped the old ramp by 12", and extended the ramp out 45" from the original 3'. I welded it on to the old ramp in strategic locations and proceeded to try it out.

As I drove the 3000 lb stump grinder across the ramp it bowed beginning where the ramp extension overlaps the old ramp and extending along the ramp extension.

My best guess at this time is that the 2"x2"x1/8" angle on the sides is not strong enough and I need to reinforce it. I'm thinking that I could just overlay another piece of angle there, of the same dimensions, and double my thickness for that area. I'm not sure how long a piece I should use, if I should go the entire length of the ramp extension or just a 12-18", or what.

This is why I would like to learn how to calculate what I need, so I don't have to be back and redo these things. Usually I overbuild things so I don't have to worry about it, but in this case I need to keep the weight down as I'm the one that has to lift this ramp twice at every stump job.

![20131112_075020[1].jpg 20131112_075020[1].jpg](https://www.tractorbynet.com/forums/data/attachments/328/328241-074455fd1102cdad15676fb91868508d.jpg)

Not sure why the pic uploaded sideways.

Thanks,

Chris