davesisk

Platinum Member

This seems like as good a forum as any to post this question... /forums/images/graemlins/cool.gif

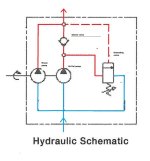

I'm referring to the type of hydraulic pump typically used on log splitters. It provides a high flow at lower pressure (to move the splitter wedge without resistance quickly) and a lower flow at high pressure (to move the wedge slower but with more force when resistance is encountered). How do these work internally to get the two different flows and pressures? Anybody know? It must be pretty simple, or it wouldn't be reliable (right?).

I have a small tractor/loader whose "transmission" is a hydrostatic drive pump and 4 hydraulic wheel motors. One of the disadvantages of this design is that you only have 1 "gear"...slow! The thought struck me that some sort of two stage pump might give you more speed when there's little resistance and more torque when it's needed...kind of like a automagic gear-selector... /forums/images/graemlins/shocked.gif Any thoughts?

Also, many hydraulic pumps can also be used as hydraulic motors. Does anyone know if that's true of any of these two-stage hydraulic pumps?

I'm not planning on modifying my current tractor, just curious. Who knows, I might decide to actually build something ludicrous one day, though!

Dave

I'm referring to the type of hydraulic pump typically used on log splitters. It provides a high flow at lower pressure (to move the splitter wedge without resistance quickly) and a lower flow at high pressure (to move the wedge slower but with more force when resistance is encountered). How do these work internally to get the two different flows and pressures? Anybody know? It must be pretty simple, or it wouldn't be reliable (right?).

I have a small tractor/loader whose "transmission" is a hydrostatic drive pump and 4 hydraulic wheel motors. One of the disadvantages of this design is that you only have 1 "gear"...slow! The thought struck me that some sort of two stage pump might give you more speed when there's little resistance and more torque when it's needed...kind of like a automagic gear-selector... /forums/images/graemlins/shocked.gif Any thoughts?

Also, many hydraulic pumps can also be used as hydraulic motors. Does anyone know if that's true of any of these two-stage hydraulic pumps?

I'm not planning on modifying my current tractor, just curious. Who knows, I might decide to actually build something ludicrous one day, though!

Dave