g8erh8er

Silver Member

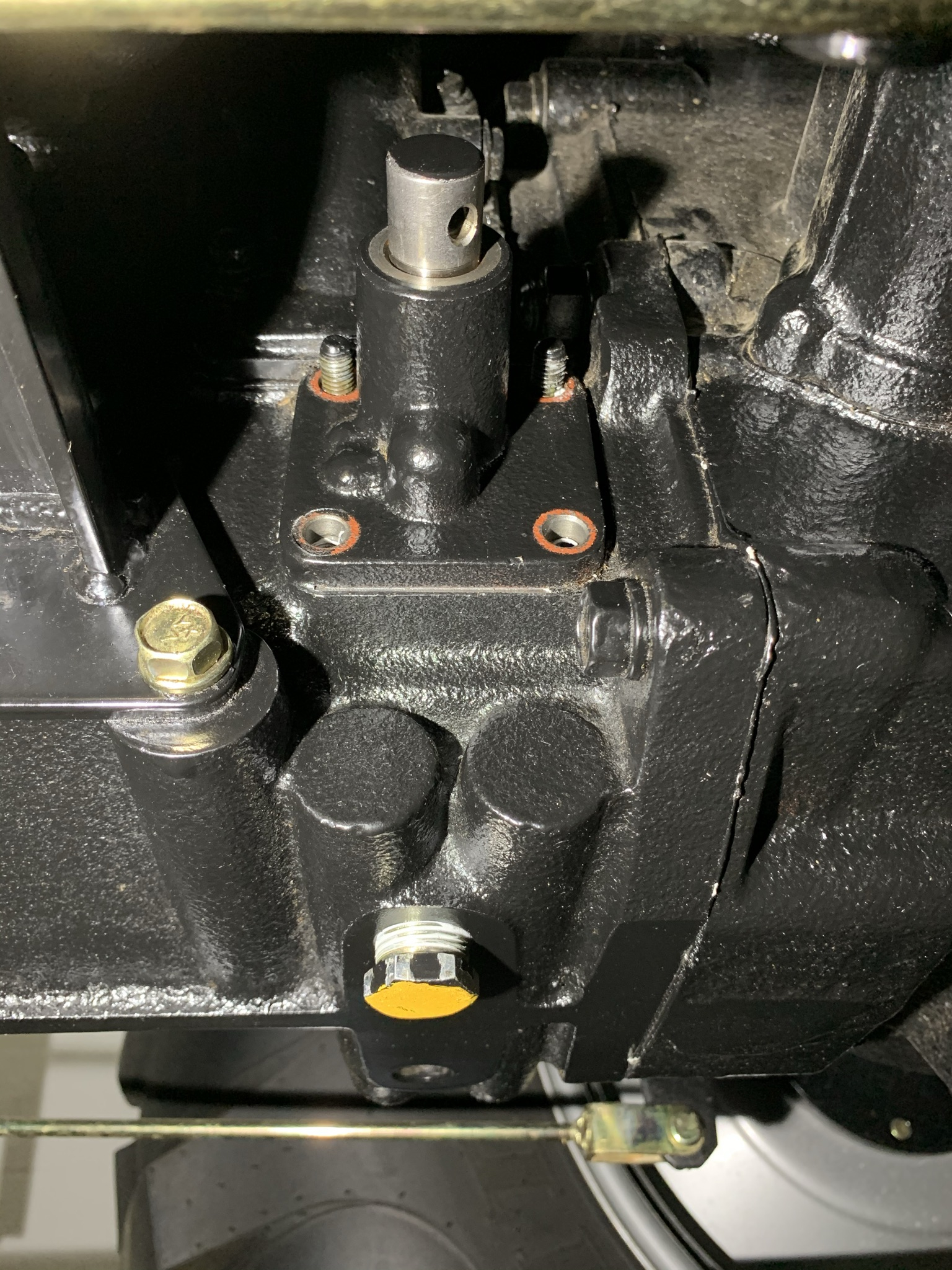

I need to take the housing off this shaft because the o-ring that keeps the shaft from leaking isn't doing its job.

Gasket maker appears to be firmly holding the housing to the transmission. I've tried some whacks with a rubber mallet with no success. Maybe try a dead blow to kind of shock the housing loose?

Trouble is, with the shaft and two upper studs, the housing is pretty well captured with limited degrees of movement so I'm not sure that additional hammer blows will do any good.

Gasket maker appears to be firmly holding the housing to the transmission. I've tried some whacks with a rubber mallet with no success. Maybe try a dead blow to kind of shock the housing loose?

Trouble is, with the shaft and two upper studs, the housing is pretty well captured with limited degrees of movement so I'm not sure that additional hammer blows will do any good.