JustBob

Member

After 3 years of wanting one, I finally decided to buy one. That is until I figured I really couldnt afford it, so i am building my own. I designed it based on my grapple frame, and 3 others I saw online.

So I went shopping and picked this up from a local machine shop, Snow's Machine & Welding.

1- 3 1/2" x 3 1/2" x 3/8 square tubing, 6.5' long

2- 4" x 2" x 3/8 tube, 48" long

2- 2" x 2" x 5/16 square tubing

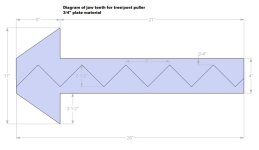

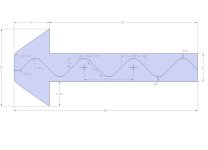

I already had the 3/4 plate, so I cut out the 8" x 24" sides for the main frame using some 2" angle for a straight edge.

I cut out the holes in the side plates for the crossmembers, then assembled to tack it together... except I somehow cut the cord on my grinder.

Still have a lot more to do tomorrow after a short trip for some more oxygen, and another power cord for the grinder, lol.

So I went shopping and picked this up from a local machine shop, Snow's Machine & Welding.

1- 3 1/2" x 3 1/2" x 3/8 square tubing, 6.5' long

2- 4" x 2" x 3/8 tube, 48" long

2- 2" x 2" x 5/16 square tubing

I already had the 3/4 plate, so I cut out the 8" x 24" sides for the main frame using some 2" angle for a straight edge.

I cut out the holes in the side plates for the crossmembers, then assembled to tack it together... except I somehow cut the cord on my grinder.

Still have a lot more to do tomorrow after a short trip for some more oxygen, and another power cord for the grinder, lol.