newbury

Super Star Member

- Joined

- Jan 8, 2009

- Messages

- 14,845

- Location

- From Vt, in Va, retiring to MS

- Tractor

- Kubota's - B7610, M4700

I thought I posted about this a few years ago but can't find it.

I've got a 40x60 shop w/ 12' ceilings. It's presently got 2 support posts near the center. The posts are 4" x 3/8" angle iron 13.5' apart.

Because of the possibility with this changing climate dumping 10" of snow on us I'm thinking of upgrading and making a support for a hoist at the same time.

I'd like to put up 2 posts adjacent to the 2 present posts with a beam running between them that I can hang a 2 ton hoist off. See red.

I'd like to be able to lift about 2K off the back of my trailer or truck, so I don't need a Shield Arc 10K gantry. I'd probably "tie" them into the present posts.

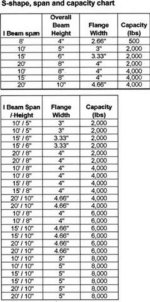

So to TBN - either what's a good site to figure out what I need for steel (pipe, column, beams?) or suggestions for what I need?

As always price is a main concern.

I've got a 40x60 shop w/ 12' ceilings. It's presently got 2 support posts near the center. The posts are 4" x 3/8" angle iron 13.5' apart.

Because of the possibility with this changing climate dumping 10" of snow on us I'm thinking of upgrading and making a support for a hoist at the same time.

I'd like to put up 2 posts adjacent to the 2 present posts with a beam running between them that I can hang a 2 ton hoist off. See red.

I'd like to be able to lift about 2K off the back of my trailer or truck, so I don't need a Shield Arc 10K gantry. I'd probably "tie" them into the present posts.

So to TBN - either what's a good site to figure out what I need for steel (pipe, column, beams?) or suggestions for what I need?

As always price is a main concern.