Blustery to 30mph+ and temp falling like a rock, 85F yesterday, 35F tomorrow morning. I had the son get the fireplace ready to burn. It's sitting there waiting for a match.

Mostly, biking and wood splitting yesterday.....He man contest soon?

You and Billy in silent competition?

Drew, I will give my wife extra kiss and hug, but I hope to make pancakes this morning if we have the ingredients.

I put the FEL back on the bigger tractor to move the haybales up front. My wife's uncle is buying them. The money will go into a "kitty" fund to buy parts to repair my friend's equipment.

Randy, have you ever tried to sew 40 oz pvc tarp material? They use it on hay disc cutter curtains. The material isn't crazy high, but the price of a complete curtain is $450 on up. Somebody could probably make a living if they could get the labor content to $200 or so.

Wife and kid are going shopping today. I'm going to put a new hazard relay in the old impala.

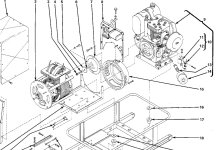

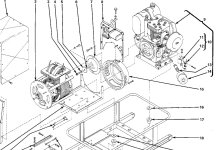

This Old Miller Roughneck: I got my dial bore gage out, and the normally trusty Teclock .0001" indicator (Japan) was sticking. I took off the back and got it moving again. Good enough for now. I haven't used it in years. Cylinder bore measured about .0015" over stock, about .001 taper, and about .0005 out of round. I believe it's within tolerance to just hone and put new rings in. These Kohlers recommend frequent oil changes, 25 hours in dusty conditions, they only hold a quart. Recommend straight 30 weight for above freezing conditions. I have figured out a possible easy way to fix the broken crankshaft end. I will make an adapter that will fit over the crank's tapered end, and provide a bushing hole to center the tools I will use to drill it out. I will have to step drill it, because I will be doing it by hand. So I might have to make multiple alignment adapters... I'm still worried about separating the engine from the welding end. It too, has a tapered end which drives the flange plate coupler. The below is all I have to go by as far as assembly detail.