JC-jetro

Elite Member

I guess the next step is to pull the steering column and see if there is something simple causing the throwout bearing to hang in a forward position. I just can't figure out what the likely cause of this trouble might be.

Thank you, JC-jetro, for taking the time and effort to help me through this, and take pictures of your tractor.

I advise against it now as you can find all you need without doing so. Again, all I was trying to tell is " you can visually check if the bearing is riding the fingers or not".

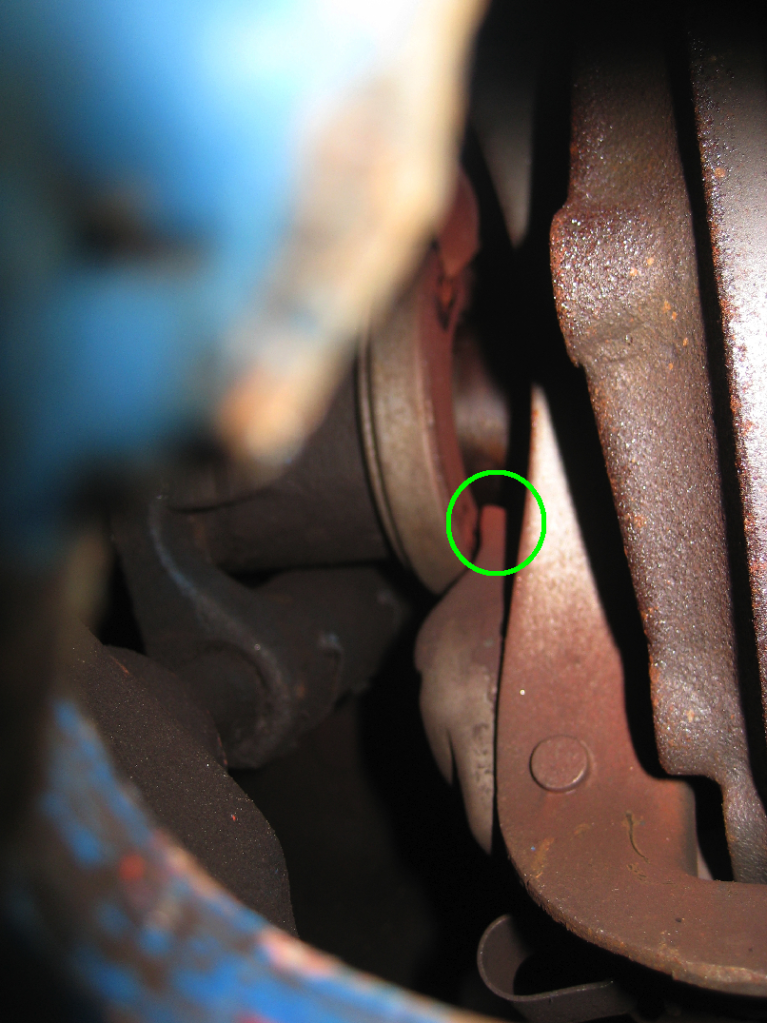

Were you able to look at the last pic I posted. Can you identify the finger visually? If you do so then it is quite easy to see if the bearing surface is touchging the fingers or not. Steerin column does not need not be taken off to verify that. It takes a flash light only. This can be done visualy without a split and 1700 access hole would afford you that. That is a great feature of this tractor.

You can verify one finger at a time though. So again going back to raising the axle to afford you turning the wheel so you can check all the 3 fingers of the pressure plate.

Do look at the picture of the pressur plate that I posted earlier on a tractor split. You must identify the fingers and verify if it is touching the bearing or not. This does not require a tractor split or steering column removal.

JC,

Last edited: