Freds

Veteran Member

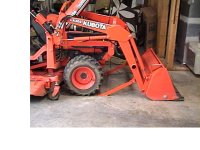

How do you get the sidearms on a 302 FEL to raise above the mounting receivers on a B7500? I thought I interpreted the instructions correctly, but I could only get them to raise up about 1". I tried different positions of the bucket and the phrase "raise the front wheels slightly" using the sidearms. When I backed out the sidearms dropped onto the tires. I ended up lifting the sidearms manually and holding them up using a 2x4. Other than that, taking it off was a piece of cake. I'm not sure how this will affect putting it back on.

Thanks,

Fred

Thanks,

Fred