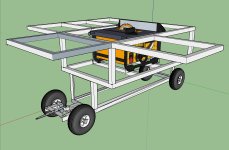

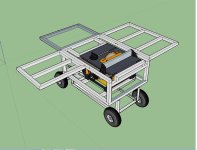

Our April Showers mostly did away with May. Not having a real roof on my shop - the tree now has leaves but they leak- was what created this need and only a very few non rainy days in over a month has helped get very little done on this project.

I am still very open to ideas and suggestions. If what I am trying doesn't fly (roll) I will be saving up for a Lowes wagon.

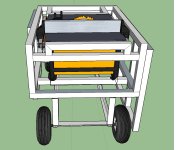

Not much to show for the time spent - I should have practiced welding or learned some photo shop. I am just a little over half done with the spindles. I bought 2 half inch black pipe T's and 3 closing nipples. The closing nipples are because I am using 5/8 inch bolts for axles.

First I attached the two t's together with a closing nipple in the 'leg' of each T. Then I sawed them apart as close as I could.

Next I screwed a tap into a 5/8 inch nut up to where full size starts. Then I clamped this onto the 'leg' of the T.

Connected the nut and T with a process I hope to one day know how to.

Hope I didn't miss blocking anything too offensive - I know I left some splatter.

You can see my method of tapping the inside of the nipple and resizing the nut after the heat treatment.

All the other openings of the T's also received half of a closing nipple. These will be drilled to accept a 5/8 inch bolt.. This can be avoided by using 3/4 inch bolts to attach to the bracket which I have made. Still thinking about drilling the 5/8 inch hole through the T. Wish I had access to a lathe.

There are much better ways and finer tools to use to do this not to mention a dry shop, but... Still need ideas and advice.