Keeping in mind that I'm kind of an "overkill specialist" :laughing: here are my thoughts -

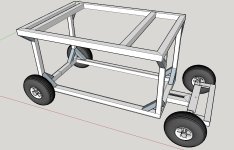

First off I really like your steering/suspension setup; without having the entire axle pivoted at center you'll have much better stability while turning, since the two steering wheels NEVER can get far enough out of line to make it effectively a "tricycle", which can be quite a bit less stable in "offroad" conditions - I also discovered (on my bandsaw stand) that I should have done the "tractor front end" setup like yours for the two non-wheeled legs - without that, I either have to find a SHIM for one leg or the other, or inflate/deflate one rear tire to take out the wobble

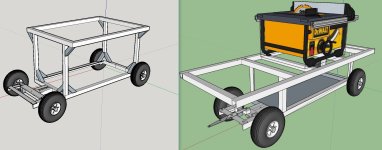

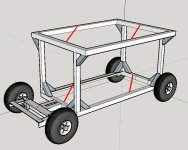

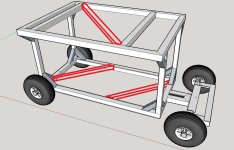

If your latest drawing is where the saw mounts will actually go, I might be tempted to NOT put gussets on the UPPER rectangle - it looks like your saw itself has a 1-piece molded "frame" that could help stiffen the upper level.

Otherwise, I'd put a SINGLE long gusset INSIDE the square area the saw mounts on - this would effectively make MOST of that upper level into 2 triangles.

The LOWER level would be (I think) MORE likely to "rack" when moving around - things like one wheel or another catching on a root or rock could conceivably cause the lower frame to get "tweaked", after which it would NEVER sit right.

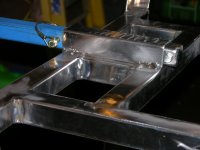

Nearly anything you do on that lower level would lessen that possibility, even a single corner-to-corner gusset that would turn that rectangle into two large triangles - in fact that way might be strongest - if I used that method though, I would use ACTUAL SQUARE TUBING. This is because angle is quite a bit more likely to bend/twist, and that diagonal member could end up in

either compression or tension, depending on WHICH rear wheel gets caught on that (hopefully mythical) root or rock.

I don't remember you mentioning WHAT that lower level will get used for; I would probably use it for a shelf to hold whatever OTHER tools I might need for the "project du jour", maybe even something like one of those "middle box" add-ons for a rollaway set, so smaller things could live in an actual drawer.

If not that, I'd put some low side-boards around that lower shelf so everything

actually GOT where I was going

Did I mention that very FEW of my "projects" are still at "version 1.0" ??