oercheron

Bronze Member

- Joined

- Dec 14, 2012

- Messages

- 57

- Location

- Aldergrove, BC

- Tractor

- 2 Kioti, 2 John Deere. None wore out yet but the '49 ain't used that much anymore

Some shots of a tool holder I welded up. Previously I had one made from plastic pipe much like some others have made. My mistake was using thin-wall pipe. After a year of use and a couple repairs it became clear that thin plastic pipe would not stand up. So I made a metal tool holder.

Height - 24", opening size approx 3" x 7". The expanded metal is 9GA, the vertical solid member is 3"channel. At top and bottom are stiffeners bent out of 3/8 round stock. The bottom is 2" x 3/16 flat which leaves a space each side for dirt & water to go through.

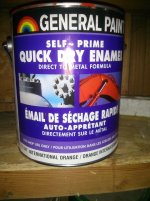

The paint used is shown, it was a very good colour match I thought. Also is very good paint, I have used it for years.

The axe sheath in the last photo is homemade from PVC pipe warmed with a propane torch and moulded to fit the axe head. There are lots of youtube videos on how to do this.

Height - 24", opening size approx 3" x 7". The expanded metal is 9GA, the vertical solid member is 3"channel. At top and bottom are stiffeners bent out of 3/8 round stock. The bottom is 2" x 3/16 flat which leaves a space each side for dirt & water to go through.

The paint used is shown, it was a very good colour match I thought. Also is very good paint, I have used it for years.

The axe sheath in the last photo is homemade from PVC pipe warmed with a propane torch and moulded to fit the axe head. There are lots of youtube videos on how to do this.

Last edited: