aeblank

Veteran Member

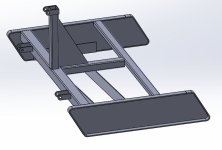

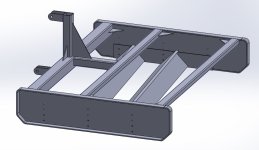

So, I really want a LPGS (Land Plane, Grader, a million other names that makes it hard to find on CraigsList).

I'll probably buy one (Land Pride or Grademaster), but thought I'd design one up just for fun.

I'm an engineer, so I figured I'd model it up and make a drawing and send it to a fabricator I know. If it comes in at sub-$1000, I might just go that way.

All that said, I don't have structural steel experience. I could figure out how strong it needs to be, pick the right thickness/size tubing, etc. etc. But....... I don't want to put that much time in it. So I figured that I'd post here. In return, I'll probably post my drawing(s) for others to take to their fab shops or build themselves.

I intend to make it adjustable like the Land Pride, but otherwise built like a Grademaster (or sort of Befco). No scarfiers. This ebay post has nice pictures (Brand New Befco 72" 3 Point Hitch Road Grader Blade | eBay).

I don't want a 2,000lb unit. People can adjust thickness/sizes to their own liking if they want. It will be a simple design too, for cost. I'm looking at a 72" unit at about 1,000#, I'd imagine. Perhaps with provisions for an add-on 55-gal drum of water for weight or something like that.

So, I need measurements.

How thick are the sides? How long are the skids? How thick are the skid shoes? What is the angle of the blades and what size angle iron is it, what is the size (and thickness!) of the cross tubing? What are the measurements of the 3-pt hookup (must be quick attach!)? Hole diameters, etc. What is a good blade source, or help me spec. a logically hard enough raw material.

I can stab at most everything and get close. But it'd be just like me to pick a randomly impossible to source tubing that doubles the price. I'm hoping by doing this post/getting feedback I can avoid all that. Heck, what grade of steel should I even call out? I'd likely leave it to my fabber, but if I can know I'm spec'ing something logical, then I will.

So, have at it, if you're interested.

I'll probably buy one (Land Pride or Grademaster), but thought I'd design one up just for fun.

I'm an engineer, so I figured I'd model it up and make a drawing and send it to a fabricator I know. If it comes in at sub-$1000, I might just go that way.

All that said, I don't have structural steel experience. I could figure out how strong it needs to be, pick the right thickness/size tubing, etc. etc. But....... I don't want to put that much time in it. So I figured that I'd post here. In return, I'll probably post my drawing(s) for others to take to their fab shops or build themselves.

I intend to make it adjustable like the Land Pride, but otherwise built like a Grademaster (or sort of Befco). No scarfiers. This ebay post has nice pictures (Brand New Befco 72" 3 Point Hitch Road Grader Blade | eBay).

I don't want a 2,000lb unit. People can adjust thickness/sizes to their own liking if they want. It will be a simple design too, for cost. I'm looking at a 72" unit at about 1,000#, I'd imagine. Perhaps with provisions for an add-on 55-gal drum of water for weight or something like that.

So, I need measurements.

How thick are the sides? How long are the skids? How thick are the skid shoes? What is the angle of the blades and what size angle iron is it, what is the size (and thickness!) of the cross tubing? What are the measurements of the 3-pt hookup (must be quick attach!)? Hole diameters, etc. What is a good blade source, or help me spec. a logically hard enough raw material.

I can stab at most everything and get close. But it'd be just like me to pick a randomly impossible to source tubing that doubles the price. I'm hoping by doing this post/getting feedback I can avoid all that. Heck, what grade of steel should I even call out? I'd likely leave it to my fabber, but if I can know I'm spec'ing something logical, then I will.

So, have at it, if you're interested.