fitterski

Gold Member

- Joined

- Oct 20, 2016

- Messages

- 377

- Location

- Nouvelle, QC

- Tractor

- 1987 Cat-426, 1991 Deutz-Dx-6.05, 2019 Husqvarna 2xHP

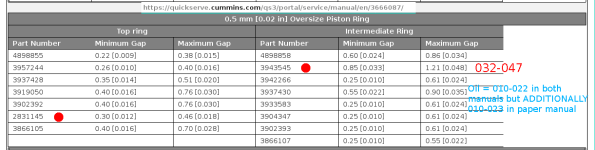

i noticed that the nanual gives end gaps as folows

page V-30

oil control: .010-.022

page V-31

top ring: .012-.018

intermediate ring: .032-.047

bottom (oil) ring: .010-.023

The oil ring spec max is incongruent .022 vs .023, this would make me lose confidence in the Cummins manual if I still had any left. In addition to that there are quite different values found on the net. I'm concerned mostly with the intermediate ring for which some widely divergent values can be found, down to as low as 1/2 the spec. The as-is gaps measured all fall within tolerance EXCEPT the intermediates ALL of which measure at around 1/2 the spec. On reaction this would prompt me to file down all the intermediates ...but wait a minute, something seems to be sticking out like a sore thumb here.

I've learned a long time ago to swing into paranoid verification mode on any doubt and here I already have 3 grounds for doubt. To begin with why would the middle ring need a much wider gap? And then why would the replacement rings all fall within spec as-is except the middle one but that in every single set?

page V-30

oil control: .010-.022

page V-31

top ring: .012-.018

intermediate ring: .032-.047

bottom (oil) ring: .010-.023

The oil ring spec max is incongruent .022 vs .023, this would make me lose confidence in the Cummins manual if I still had any left. In addition to that there are quite different values found on the net. I'm concerned mostly with the intermediate ring for which some widely divergent values can be found, down to as low as 1/2 the spec. The as-is gaps measured all fall within tolerance EXCEPT the intermediates ALL of which measure at around 1/2 the spec. On reaction this would prompt me to file down all the intermediates ...but wait a minute, something seems to be sticking out like a sore thumb here.

I've learned a long time ago to swing into paranoid verification mode on any doubt and here I already have 3 grounds for doubt. To begin with why would the middle ring need a much wider gap? And then why would the replacement rings all fall within spec as-is except the middle one but that in every single set?