joshuabardwell

Elite Member

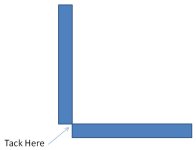

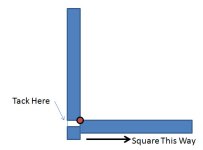

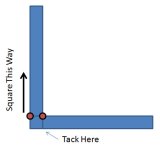

I wonder if anybody more experienced could give me tips on correcting for warpage. Like, recently I tried to build, basically a three-sided channel. No matter how carefully I aligned the side walls before welding, afterwards, they were out of true. I got a suggestion to fix it by clamping them and then beating on the welds with a big mallet, which worked, but surely that's not how pros do it. What do the pros do? Do they torch the joints after welding and bend the pieces into place? Or do they do something beforehand that prevents the warpage? I see all this stuff out there in the world, and it sure looks square, and I have no idea how it's accomplished. I know that warping is just a part of welding, but if that's true, then how does anybody make anything that's actually a 90-degree angle?

Now that I write out the question, I wonder if warpage isn't really the right word for what I'm asking about. I know about backstepping and stitch welding and other techniques for correcting warpage. I guess what I'm really asking about is how to compensate for the shrinking/expansion of the weld joint itself, that pushes right angles out of true.

Now that I write out the question, I wonder if warpage isn't really the right word for what I'm asking about. I know about backstepping and stitch welding and other techniques for correcting warpage. I guess what I'm really asking about is how to compensate for the shrinking/expansion of the weld joint itself, that pushes right angles out of true.