BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

I mostly use this, diluted as recommended

https://www.amazon.com/Hougen-11742...F8&qid=1545639129&sr=8-9&keywords=hougen+lube

Mix it in these (for extended projects)

https://www.amazon.com/gp/product/B00AQV14SA/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

or these for smaller jobs

https://www.amazon.com/gp/product/B00NQ8DO3I/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

I also have one of the stick lubes, only use it when I can't keep the drill vertical (so far, not often at all)

I haven't quite got as brave as Terry on the compressed air, but probably will eventually - I'd need to set up a record-keeping method for # of cuts/material/thickness for one specific cutter (preferably NOT one of the bigger one$$) first.

One thing the Hougen info stresses is to ALWAYS put enough pressure on the drill to hear it "working", i.e. loaded down a bit - they say you'll get premature wear either "taking it easy", and/or "pecking at it".

One of my most-used cutters is the 21/32" by 2" DOC, all my "tinker toy" pieces are 2" male/female receiver tube and that size gives just enough clearance for a 5/8" pin or bolt not to bind. I had my local machine shop turn down that cutter a ways into the mount so it could cut both sides of 2.530" OD tube, and have cut probably 250-300 holes thru both walls of 2" and 2.53" .250 wall, ALWAYS with constant feed lube, well-loaded. That cutter (timed cuts) is still cutting like new. If it ain't broke....

"I had thought about converting a junk drill press, but then thought there was a good chance the table would not be square to the column and I would have to fix that first. Then I also thought about using an xy table, but decided it would not be all that well adapted to what I usually do. I did NOT think of mounting the drill to a vise!"

For me, each has its uses - I'll be adding a "dead drill press" to the mix if/when I find a TABLE model that's bigger than a toy - right now, even with the 4" stroke I have problems with getting the right HEIGHT for some things - the drill press table would help with that (would likely need to thicken the table for magnet holding power)

Reason I want a TABLE model is the column "stiffener" is shorter on table models (the table would need to go pretty low for this), not sure how I'd go about machining that stiffener down til I get a lathe. Could probably use the rotary table and a roughing mill on my mill...

IF that's not clear, look online at pics of table drill presses (the base) compared to floor models -

Another trick that works for me - I've bought several METRIC cutters, always just a few thou bigger than SAE sizes I use a lot - this gives me a hole with just enough slop not to need a hammer to drive a bolt in. I have Evolution's catalog, edited to show the cutters I have - if it's not too big I'll attach the pdf here - if that works, you can see that ALL the metric cutters I've marked are really just SAE with "built-in clearance"

Looks like it might've worked. I like Evolution's cutters AND their containers, plus they don't make you buy a pilot SEPARATELY like some others - nice thing about their containers is MOST are the same diameter, up til the cutter is too big to fit it - - One of those "oversize shoe box" totes, a piece of 2x6 and a forstner bit and "voila"

- One of those "oversize shoe box" totes, a piece of 2x6 and a forstner bit and "voila"  (couple more cutters and I'll be re-thinking that one

(couple more cutters and I'll be re-thinking that one  )

)

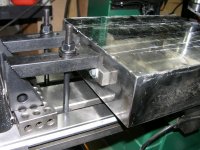

There's more; found more pics of the "vise table build" - but my valerian's kickin' in, so probably manana... Steve

https://www.amazon.com/Hougen-11742...F8&qid=1545639129&sr=8-9&keywords=hougen+lube

Mix it in these (for extended projects)

https://www.amazon.com/gp/product/B00AQV14SA/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

or these for smaller jobs

https://www.amazon.com/gp/product/B00NQ8DO3I/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

I also have one of the stick lubes, only use it when I can't keep the drill vertical (so far, not often at all)

I haven't quite got as brave as Terry on the compressed air, but probably will eventually - I'd need to set up a record-keeping method for # of cuts/material/thickness for one specific cutter (preferably NOT one of the bigger one$$) first.

One thing the Hougen info stresses is to ALWAYS put enough pressure on the drill to hear it "working", i.e. loaded down a bit - they say you'll get premature wear either "taking it easy", and/or "pecking at it".

One of my most-used cutters is the 21/32" by 2" DOC, all my "tinker toy" pieces are 2" male/female receiver tube and that size gives just enough clearance for a 5/8" pin or bolt not to bind. I had my local machine shop turn down that cutter a ways into the mount so it could cut both sides of 2.530" OD tube, and have cut probably 250-300 holes thru both walls of 2" and 2.53" .250 wall, ALWAYS with constant feed lube, well-loaded. That cutter (timed cuts) is still cutting like new. If it ain't broke....

"I had thought about converting a junk drill press, but then thought there was a good chance the table would not be square to the column and I would have to fix that first. Then I also thought about using an xy table, but decided it would not be all that well adapted to what I usually do. I did NOT think of mounting the drill to a vise!"

For me, each has its uses - I'll be adding a "dead drill press" to the mix if/when I find a TABLE model that's bigger than a toy - right now, even with the 4" stroke I have problems with getting the right HEIGHT for some things - the drill press table would help with that (would likely need to thicken the table for magnet holding power)

Reason I want a TABLE model is the column "stiffener" is shorter on table models (the table would need to go pretty low for this), not sure how I'd go about machining that stiffener down til I get a lathe. Could probably use the rotary table and a roughing mill on my mill...

IF that's not clear, look online at pics of table drill presses (the base) compared to floor models -

Another trick that works for me - I've bought several METRIC cutters, always just a few thou bigger than SAE sizes I use a lot - this gives me a hole with just enough slop not to need a hammer to drive a bolt in. I have Evolution's catalog, edited to show the cutters I have - if it's not too big I'll attach the pdf here - if that works, you can see that ALL the metric cutters I've marked are really just SAE with "built-in clearance"

Looks like it might've worked. I like Evolution's cutters AND their containers, plus they don't make you buy a pilot SEPARATELY like some others - nice thing about their containers is MOST are the same diameter, up til the cutter is too big to fit it -

- One of those "oversize shoe box" totes, a piece of 2x6 and a forstner bit and "voila"

- One of those "oversize shoe box" totes, a piece of 2x6 and a forstner bit and "voila" There's more; found more pics of the "vise table build" - but my valerian's kickin' in, so probably manana... Steve