RobertBrown

Veteran Member

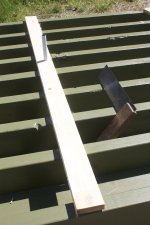

Glad to see you followed through on this Loyd. Looks like you got a plan.

Looking forward to the results:thumbsup:

When is the first pour?

Looking forward to the results:thumbsup:

When is the first pour?