Does anyone know if there are supposed to be bushings that the bolts fit through at the point where the tail wheel assembly attaches to the shredder/stabilizer arms. The dealership put bolts in but they've broken twice and this time the whole tail wheel assembly broke off and I bent my drive shaft.

I didn't even hit anything with the shredder - it's just from running it over rough ground. It seems as if there should be a sleeve or something that the bolt goes through. But all it came with and all the mechanic put back in after it broke were bolts.

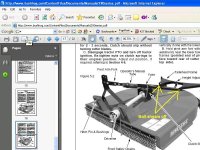

I've attached a photo from the manual with an arrow at the problem point - anyone else have this problem?

I didn't even hit anything with the shredder - it's just from running it over rough ground. It seems as if there should be a sleeve or something that the bolt goes through. But all it came with and all the mechanic put back in after it broke were bolts.

I've attached a photo from the manual with an arrow at the problem point - anyone else have this problem?